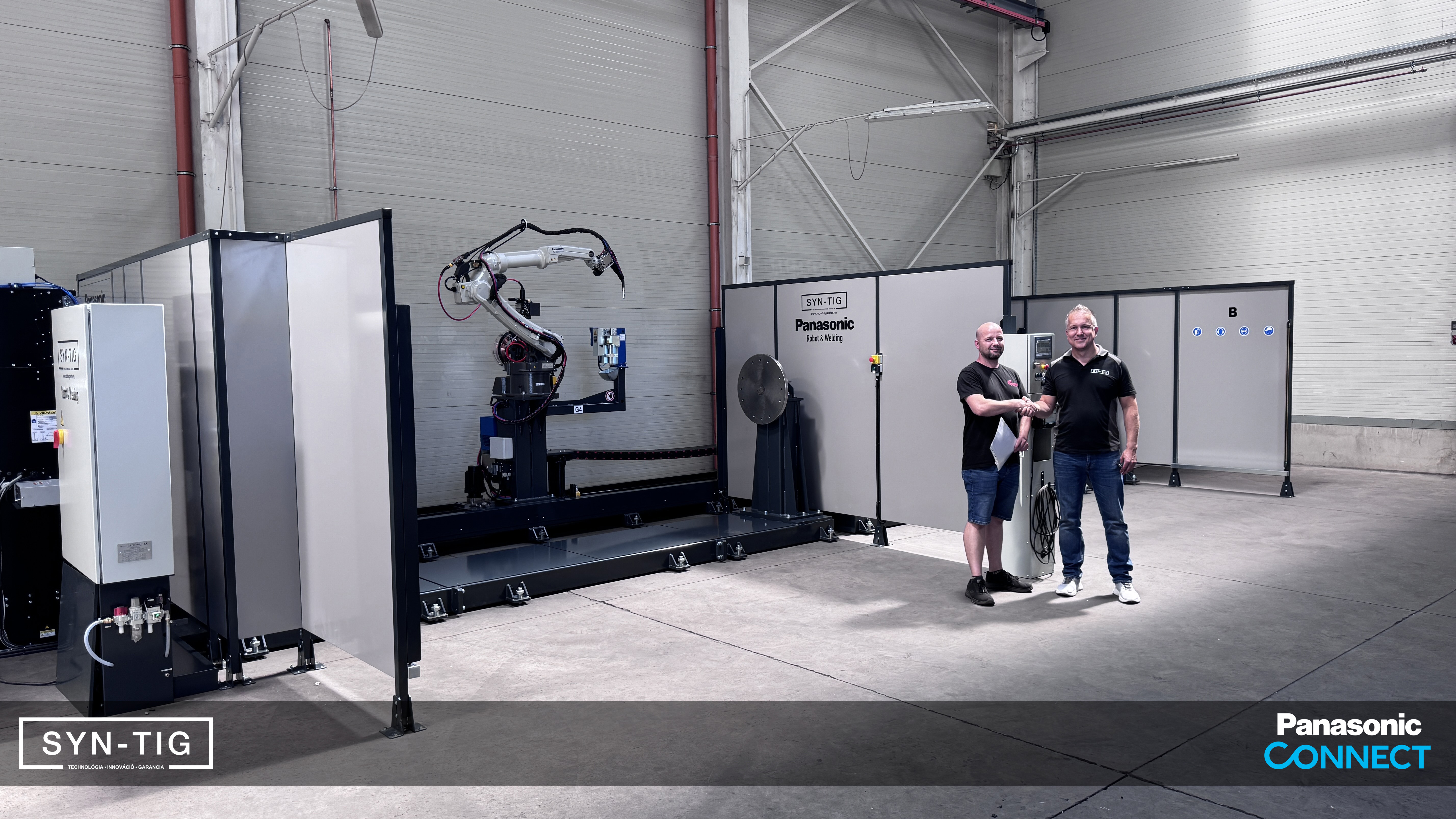

Panasonic PA-E-Frame-2000 welding robot system installation

We are proud to present our latest in-house developed system, the result of our company’s engineering expertise and continuous innovation. The system is equipped with a Panasonic TM-2000WG4 welding robot and Super Active welding technology, ensuring excellent weld quality and high productivity. It features an in-house developed 8-meter travel track and two in-house designed positioners, each with a 2-ton load capacity, providing flexible and precise operation throughout the production process.

Main technical parameters:

-

Robot: Panasonic TM-2000WG4 S-AWP

-

Welding power source: Panasonic WG4 350A

-

Welding cable: Panasonic S-AWP Super Active

-

Positioning equipment:

-

2 × PD2000 single-axis positioner – 2-ton load capacity / work area

-

1 × linear travel track – 8 m length, approx. 7 m effective travel range

-

The complete design, manufacturing, and installation of the system were carried out by our in-house team.

This system represents cutting-edge technology, enabling precise, reliable, and high-speed welding even in the most complex production environments. Thanks to the Super Active Welding – Active Wire technology, heat input is reduced, weld quality is improved, and the need for post-processing is minimized. This innovation opens up new possibilities in efficiency and productivity, and we are proud to have developed it entirely in-house – from design to implementation.