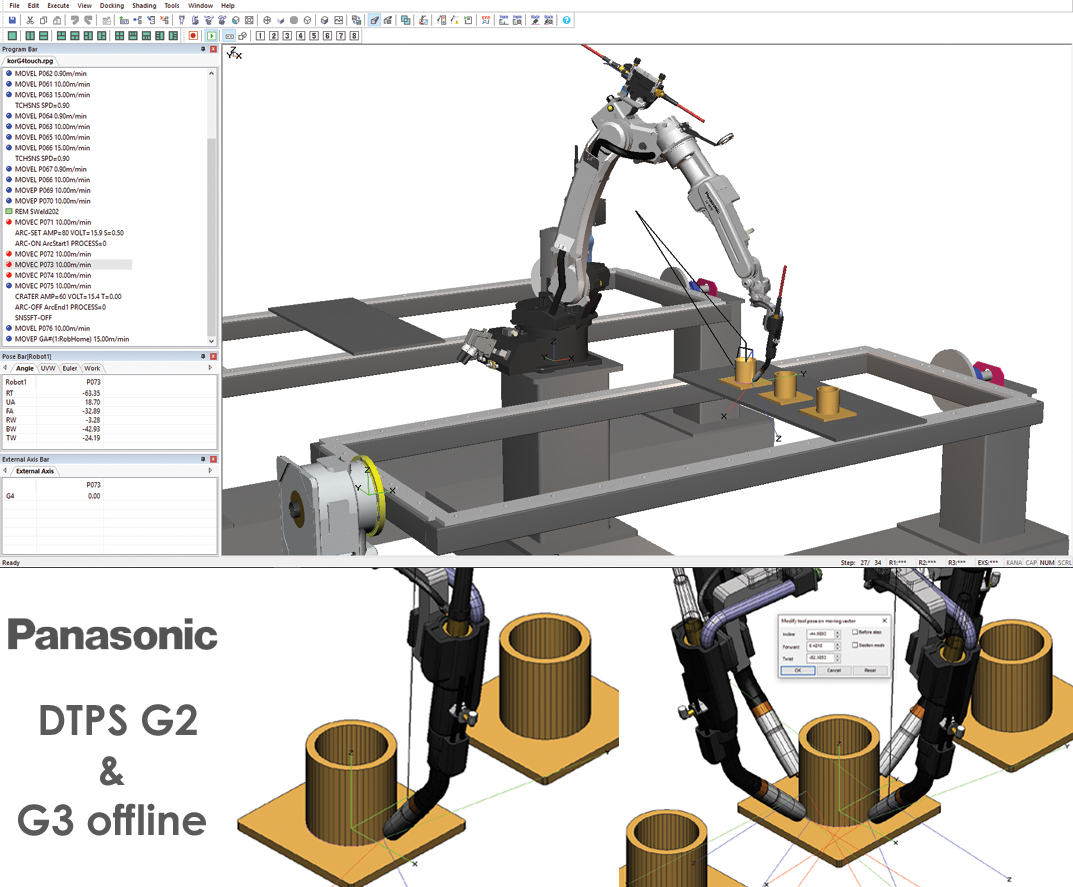

DTPS Offline Programming & Simulation – Training Course

Our DTPS (Desktop Programming & Simulation System) training is designed to equip participants with the knowledge and practical skills needed to efficiently program and simulate Panasonic industrial robots offline.

DTPS is specialized software developed by Panasonic exclusively for Panasonic robots, allowing users to create, edit, and verify robot programs in a virtual 3D environment—without interrupting live production. During the training, participants will learn how to seamlessly transfer programs from a PC to the robot controller and make the most of DTPS’s powerful features.

Key topics covered in the training:

-

Introduction to the DTPS software interface

-

Creating and editing robot programs offline

-

Simulating robot motion in 3D

-

Transferring programs to the robot controller

-

Performing accessibility analysis with collision detection

-

Calculating cycle time, analyzing number of welds, weld seam lengths, and wire consumption

-

Checking and modifying system parameters

Benefits of offline programming:

-

No need to stop production for programming tasks

-

Programs can be developed conveniently in the office

-

Significant time and cost savings

-

Better process planning and risk reduction through simulation

This hands-on training ensures that participants become confident in using DTPS for efficient, precise, and safe robot programming. Ideal for engineers, programmers, and technicians working with Panasonic welding robots.