Panasonic WG4/WGH4 robot welding system - NEW

The WG4 and WGH4 are the flagship models of welding robots.

The Panasonic WG4 and WGH4 models are the most advanced welding robots, helping to overcome the company's challenges with innovative solutions. These robots support production optimization with improved welding capabilities, easy operation and increased safety.

Highly accurate and efficient welding experience

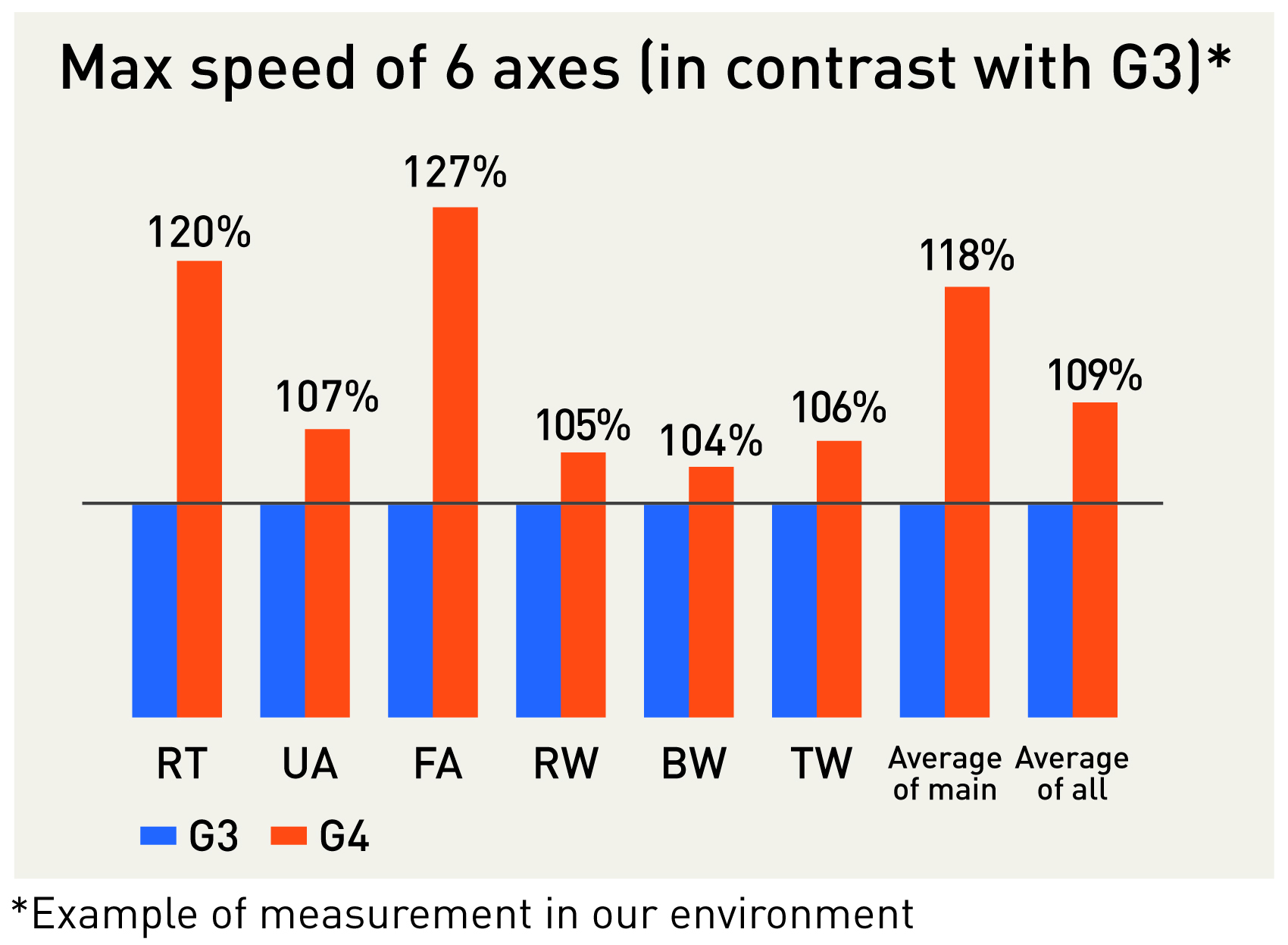

The maximum speed of each axis has improved by up to 27% by fine-tuning acceleration/ deceleration control. The operation algorithm has also been reviewed to improve locus accuracy. These improvements can significantly reduce work lasses that affect productivity in demanding workplaces. Further, this helps to improve product quality, which is indispensable to business success.

Easier to use with touch panel and 3D display

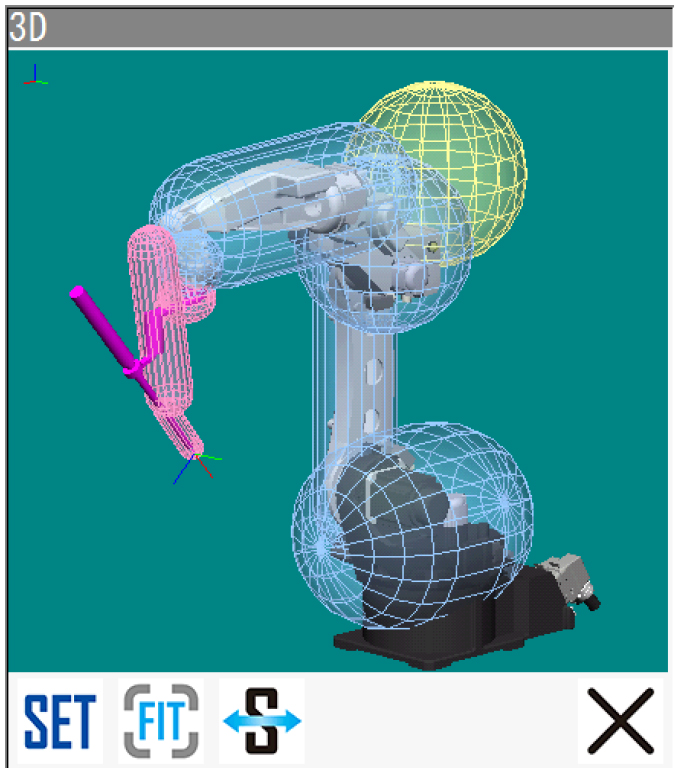

Equipped with a touch panel with a resolution 1.6 times greater than that of G3, which can be operated with work gloves on, and a 3D engine adopted for the first time, this controller realizes a high-definition 3D display and intuitive operations, herefore making it easier to use.

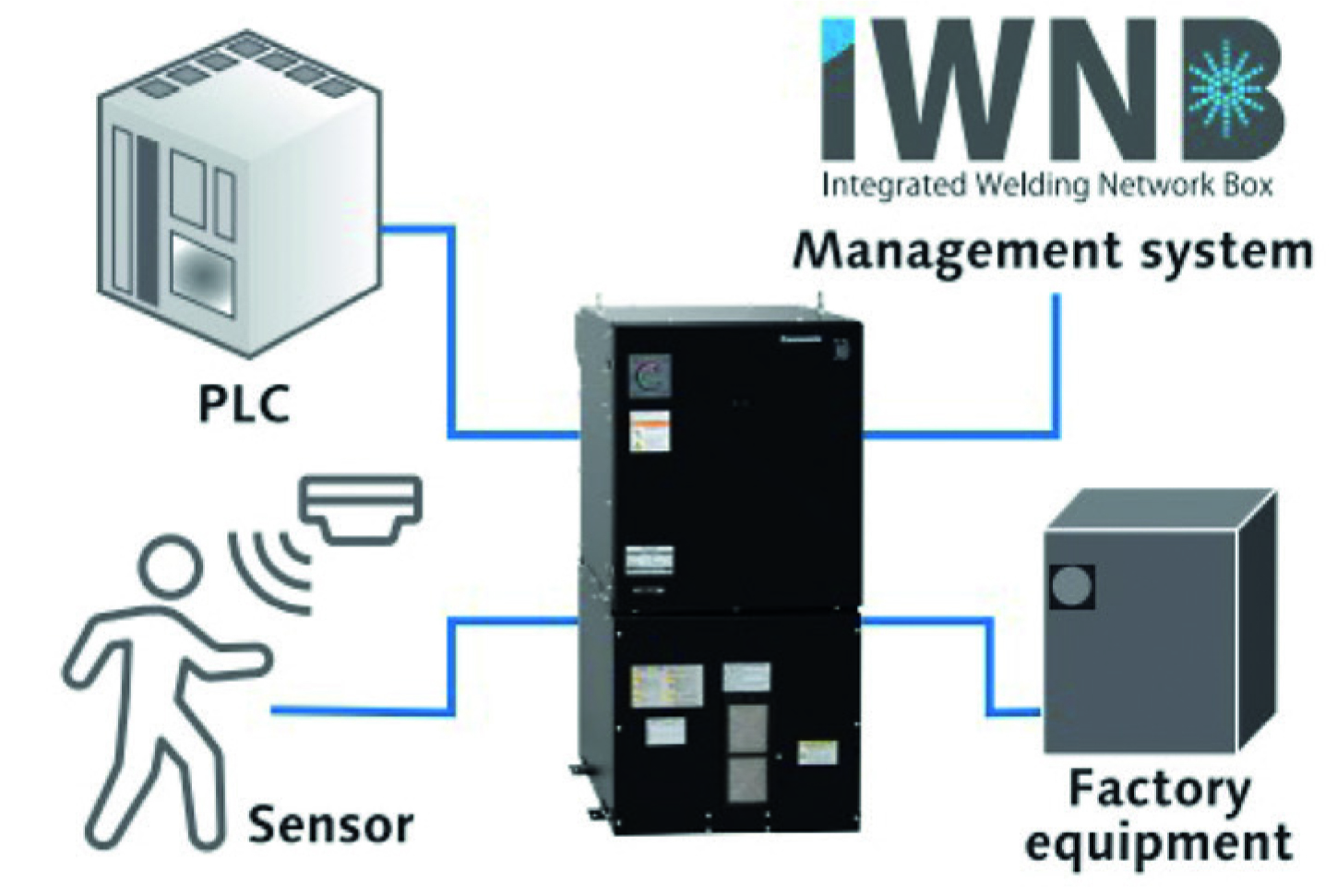

For manufacturing where everything is connected

The G4 controller realizes various functions not available with G3 by utilizing its high speed and parallel processing capabilities. In particular, the adoption of open communication specifications called OPC UA and software-based functional safety with excellent flexibility are typical examples. Connection with new sensors for safety and other devices for data collection or automation will be made easier without any compatibility restrictions with additional devices or hardware limitations.

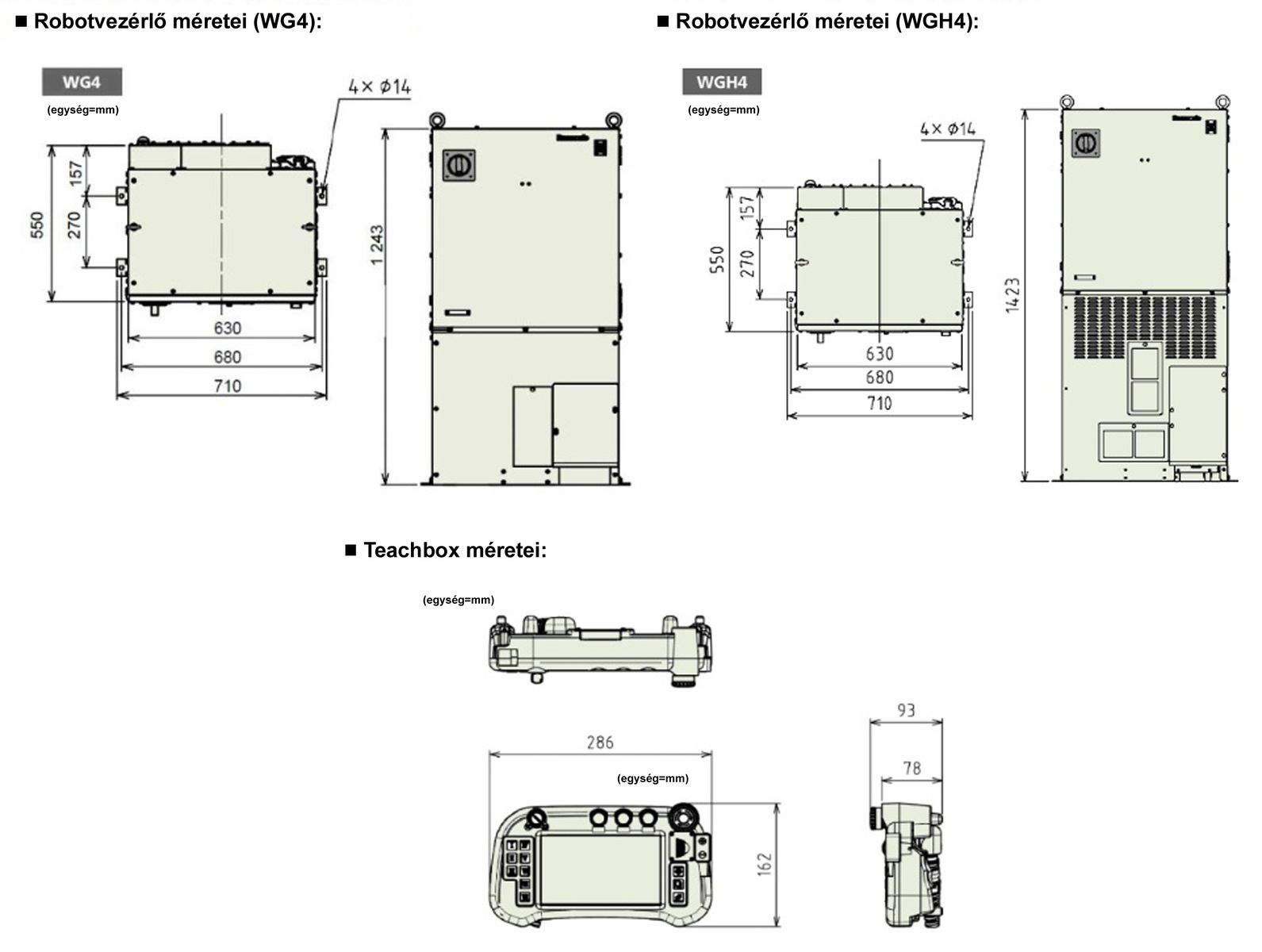

Cables arranged on the back to save space

The primary side input line and connection cables are arranged on the back and the TP Cable is arranged on the front to reduce projections on the side*.

Features

-

Reduces spatter by approximately 60% with the MTS-CO2 welding method (WG4)

-

Welding control optimization according to robot posture reduces cycle time (WG4 / G4)

-

The teach pendant equipped with a touch panel further improves ease of use (WG4 / G4)

-

Eliminating the need for an external step-down transformer reduces the man-hours required for setting up at sites outside Japan (WG4 / G4)

-

The conformance to the OPC UA standard facilitates integration with peripheral devices (WG4 / G4)

-

The software-based safety mechanism enables more flexible and safer work environments (WG4 / G4)

Speed comparison video WG3 - WG4.

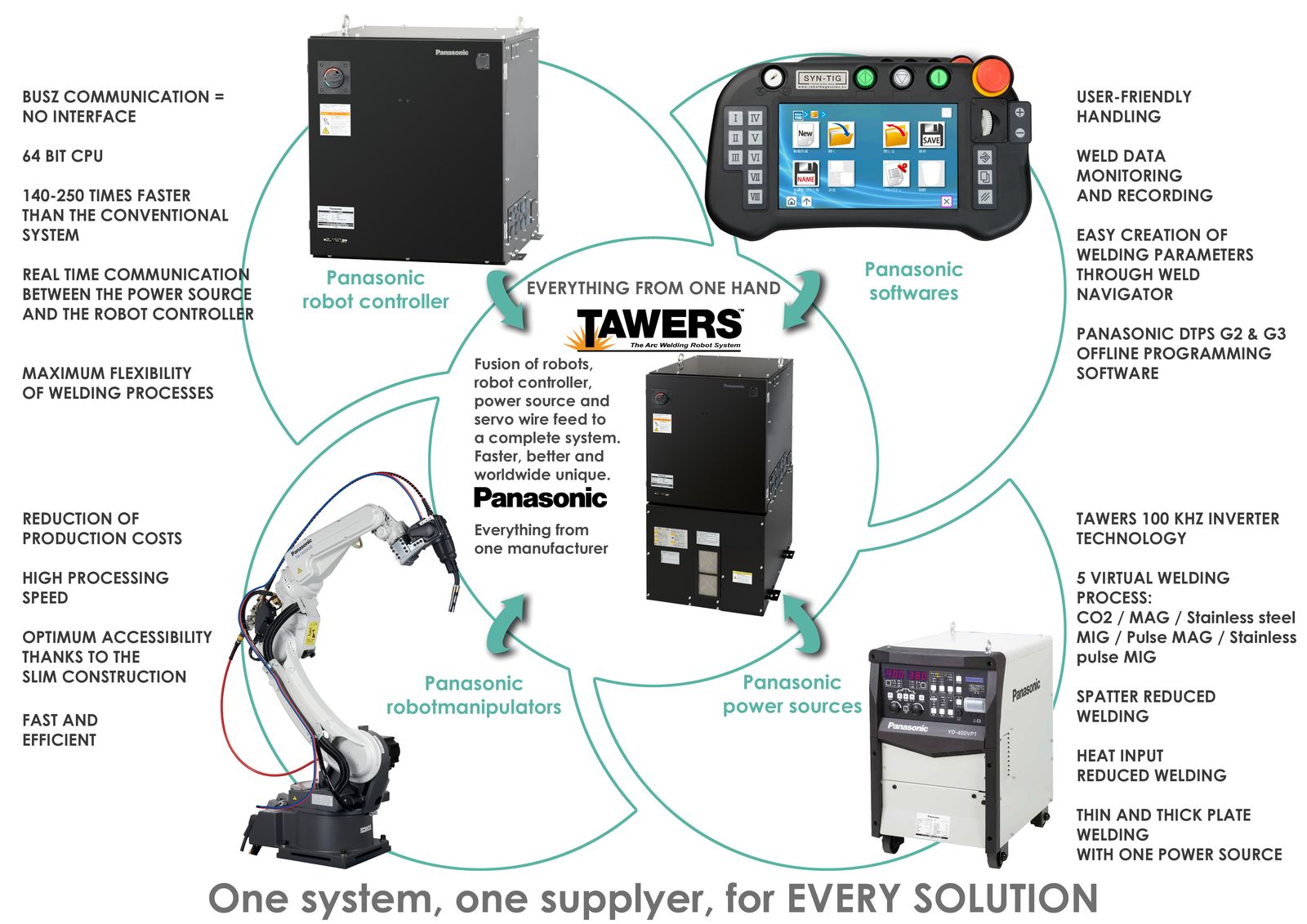

Panasonic G4 Robot Controller and Programming Tool

The Panasonic G4 robot controller is the latest generation controller in the TAWERS (The Arc Welding Robot System) system, specifically designed for arc welding robots. The G4 controller offers a number of improvements over previous models, particularly in terms of welding quality, productivity and system integration.

Measures

Key Features and Benefits

- Integrated Welding Power Source: Thanks to TAWERS technology, the robot controller, welding power source, and servo wire feeder share a single common CPU, eliminating interface issues and increasing system reliability.

- Spatter Reduction: By using the MTS-CO₂ welding method, spatter can be reduced by up to 60%, especially during high-current welding.

- Faster Axis Movement: With finely tuned acceleration and deceleration control, the maximum speed of individual axes can increase by up to 27%, reducing cycle time and boosting productivity.

- Touchscreen Teach Pendant: The glove-friendly, high-resolution touchscreen and 3D display make robot programming and early error detection easier.

- OPC UA Support: The open communication interface enables easy system integration with other industrial devices, such as sensors and cameras, promoting Industry 4.0 compatibility.

- Offline Programming (DTPS): Using DTPS software, welding processes can be programmed and simulated in advance, reducing downtime and increasing manufacturing flexibility.

| Specification | WG4 | WGH4 |

|---|---|---|

| Memory Capacity | 40,000 points | 40,000 points |

| Position Control Method | Software server system | Software server system |

| External Memory I/F |

TP: SD card slot × 1, USB 2.0 |

TP: SD card slot × 1, USB 2.0 |

| Controllable Axes | Simultaneously 6 axes (max. 27 axes) | Simultaneously 6 axes (max. 27 axes) |

| Input/Output Signals |

Dedicated signals: 6 inputs, 8 outputs General-purpose signals: 40 inputs, 40 outputs Safety input/output: 8 inputs, 8 outputs |

Same as WG4 |

| Input Power Supply | 380–440 V (±10%), 50 Hz / 60 Hz | 380–440 V (±10%), 50 Hz / 60 Hz |

| Input Cable | Min. 14 mm² | Min. 14 mm² |

| Grounding | Min. 14 mm² | Min. 14 mm² |

| Applicable Welding Methods | CO₂/MAG / Stainless MIG Pulse MAG Stainless Steel Pulse MIG | CO₂/MAG / Stainless MIG Pulse MAG Stainless Steel Pulse MIG |

| Welding Current Range | 30 – 350 A DC | 40 – 500 A DC |

| Output Voltage | 12 V – 36 V DC | 16 V – 50 V DC |

| Rated Duty Cycle (10 min) |

CO₂/MAG / Stainless MIG: 310 A: 100% 311–350 A: 80% Pulse MAG / Stainless MIG: 270 A: 100% 271–350 A: 60% |

CO₂/MAG / Stainless MIG: 450 A: 100% 451–500 A: 80% Pulse MAG / Stainless MIG: 450 A: 100% 451–500 A: 60% |

Touchscreen Programming Device (Teach Pendant) – Even Simpler Operation

The latest generation teach pendant is equipped with a touchscreen, further enhancing user-friendliness for WG4 and WGH4 controllers.

New touchscreen interface while maintaining the familiar control logic.

Operable with gloves, eliminating the need to remove protective equipment during use.

Clean display with integrated function buttons for a more intuitive user experience.

Zoomable characters reduce the risk of pressing the wrong button and significantly improve readability.

This development is especially beneficial in industrial environments where fast, accurate, and ergonomic operation is a top priority.

Panasonic Integrated Welding Power Sources – TAWERS System

General Overview

Panasonic welding robots equipped with integrated TAWERS power sources (using Panasonic TM or TL robot manipulators) are highly suitable for various MIG/MAG/TIG welding processes. By leveraging the inverter-based welding power source integrated into the robot controller (shared CPU), the system enables optimal welding performance through a fully synergic and unified control architecture.

Panasonic TAWERS welding robots can be easily applied to MIG, MAG, and TIG processes. Being an integrated system, for tasks like MIG aluminum welding, only a MIG base package (wire guide spiral, rollers, etc.), a water-cooled Panasonic welding torch, and Panasonic MIG ALU software are required. For DC TIG (HF) welding, a TIG torch and TIG software option are needed.

WG4 Inverter Welding Power Source

Power Output: 30A – 350A

Duty Cycle:

-

80% for CO₂, MAG, and stainless MIG welding

-

60% for pulse MAG and stainless pulse MIG welding

Supported Welding Processes:

-

CO₂

-

MAG

-

Stainless MIG

-

Pulse MAG

-

Stainless Pulse MIG

Additional Features:

-

Lift Start and Lift End functions

-

Touch sensor function (optional)

-

Auto Extension for horizontal seam tracking (optional)

-

Weld Data Management software for weld data logging (optional)

And much more…

WGH4 Inverter Welding Power Source

Power Output: 40A – 500A

Duty Cycle:

- 80% for CO₂, MAG, and stainless MIG welding

-

60% for pulse MAG and stainless pulse MIG welding

Supported Welding Processes:

-

CO₂

-

MAG

-

Stainless MIG

-

Pulse MAG

-

Stainless Pulse MIG

Additional Features:

-

Lift Start and Lift End functions

-

Touch sensor function (optional)

-

Auto Extension for horizontal seam tracking (optional)

-

Weld Data Management software for weld data logging (optional)

And much more…

Summary

Panasonic WG4 and WGH4 robots represent the latest technology in the welding robot market, particularly in manufacturing optimization and ease of operation. The WG4 is an upgraded version of the WG3, while the WGH4 offers higher power and broader application possibilities. A professional consultation is recommended before choosing the right model to ensure it meets specific project needs.