Syntig references

Foreword

We are proud to be able to install unique and efficient welding robot systems for our partners in various industrial segments. Below we present some of our highlight projects, which clearly demonstrate our professional expertise, innovation capabilities and close cooperation with our customers. In all our installations, we strive to ensure the highest level of quality and reliability, tailored to the specific needs of the given industry. More installations and information can be found in the blog section, by clicking here.

Welding robot system PA-E-Frame-S

The main features of the system:

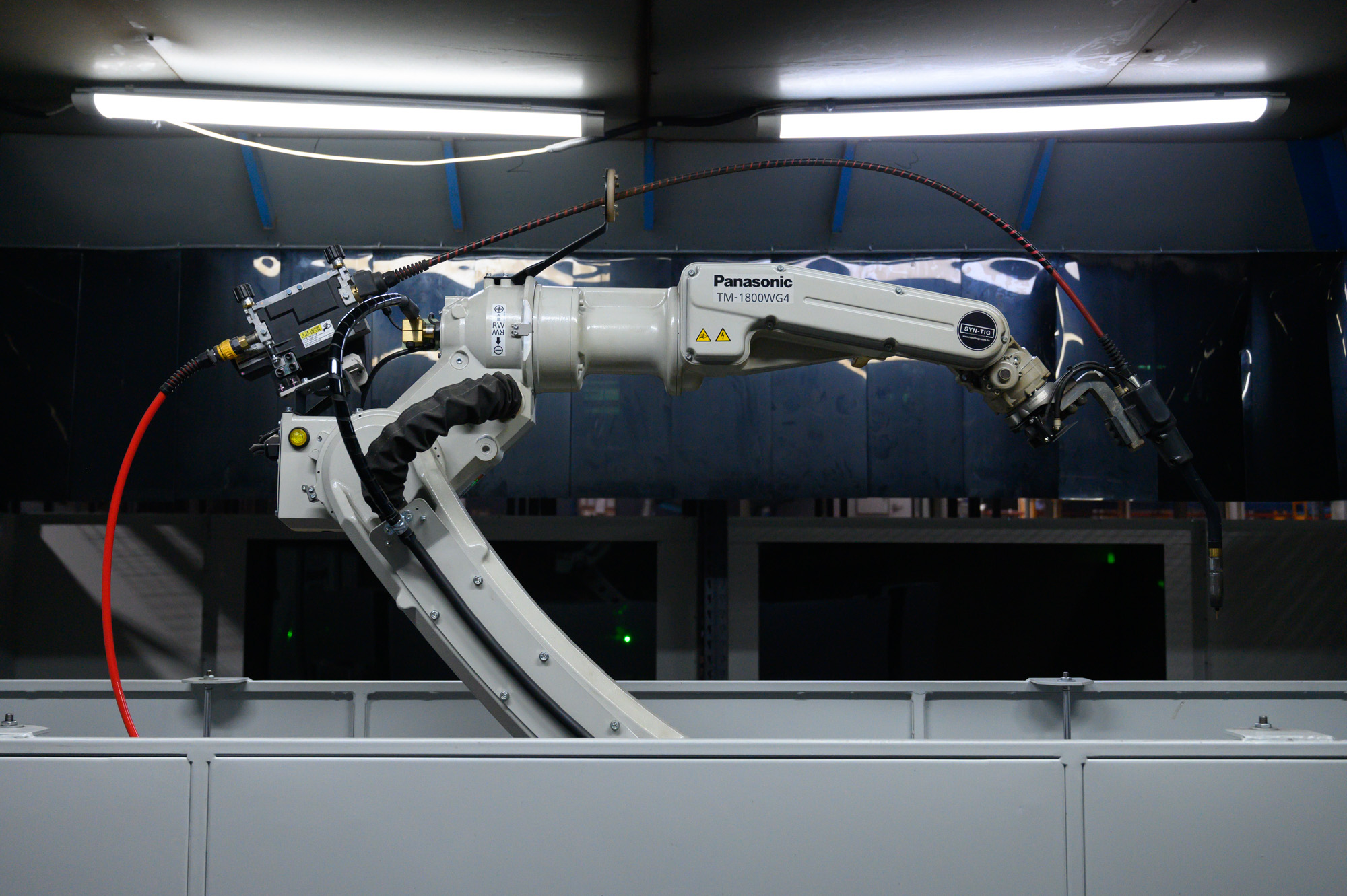

System design: Panasonic PA-E-Frame-S welding robot system

Robot type: Panasonic TM-1800WG3 SAWP

Power source: Panasonic TAWERS 350A integrated

Welding torch: Panasonic 350A separated water cooled SAWP

Positioner: 2 x Panasonic PD500 + 1 x 6m long linear shifter with 5m movability

Working area: 2 x (L=3 000mm x d=1 300mm)

Welding robot system PA-H-Frame-2DK SAWP

Main features of the system

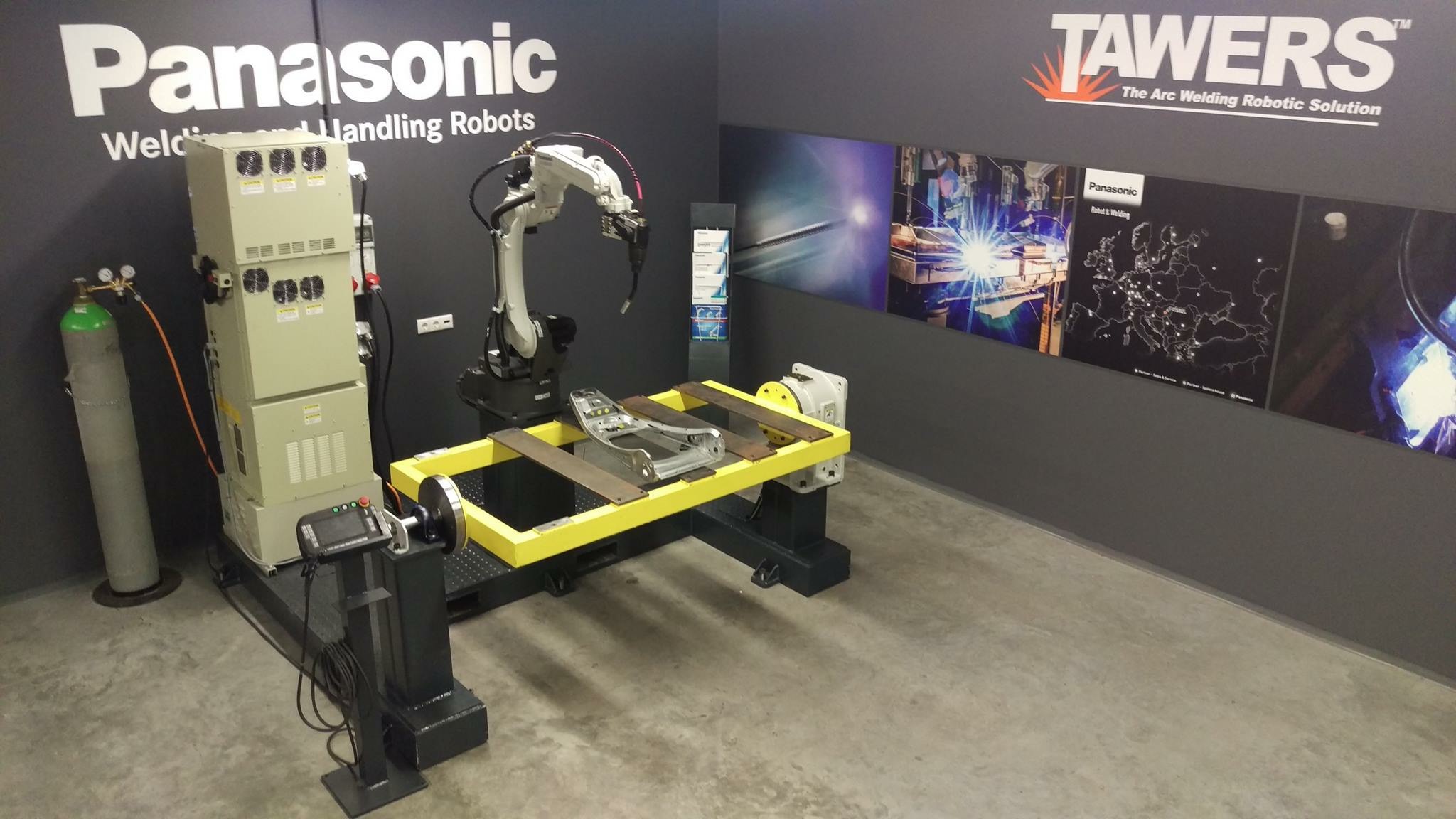

System type: Panasonic PA-H-Frame-2DK SAWP

Robot type: Panasonic TM-1800WG3

Power source: Panasonic TAWERS 350A integrated

Torch: Panasonic Super Active, water cooled

Positioner: 2 x Panasonic RJC300 (RJC62 Tilt/Turn)

Welding robot system PA-H-Frame-S

The main features of the system:

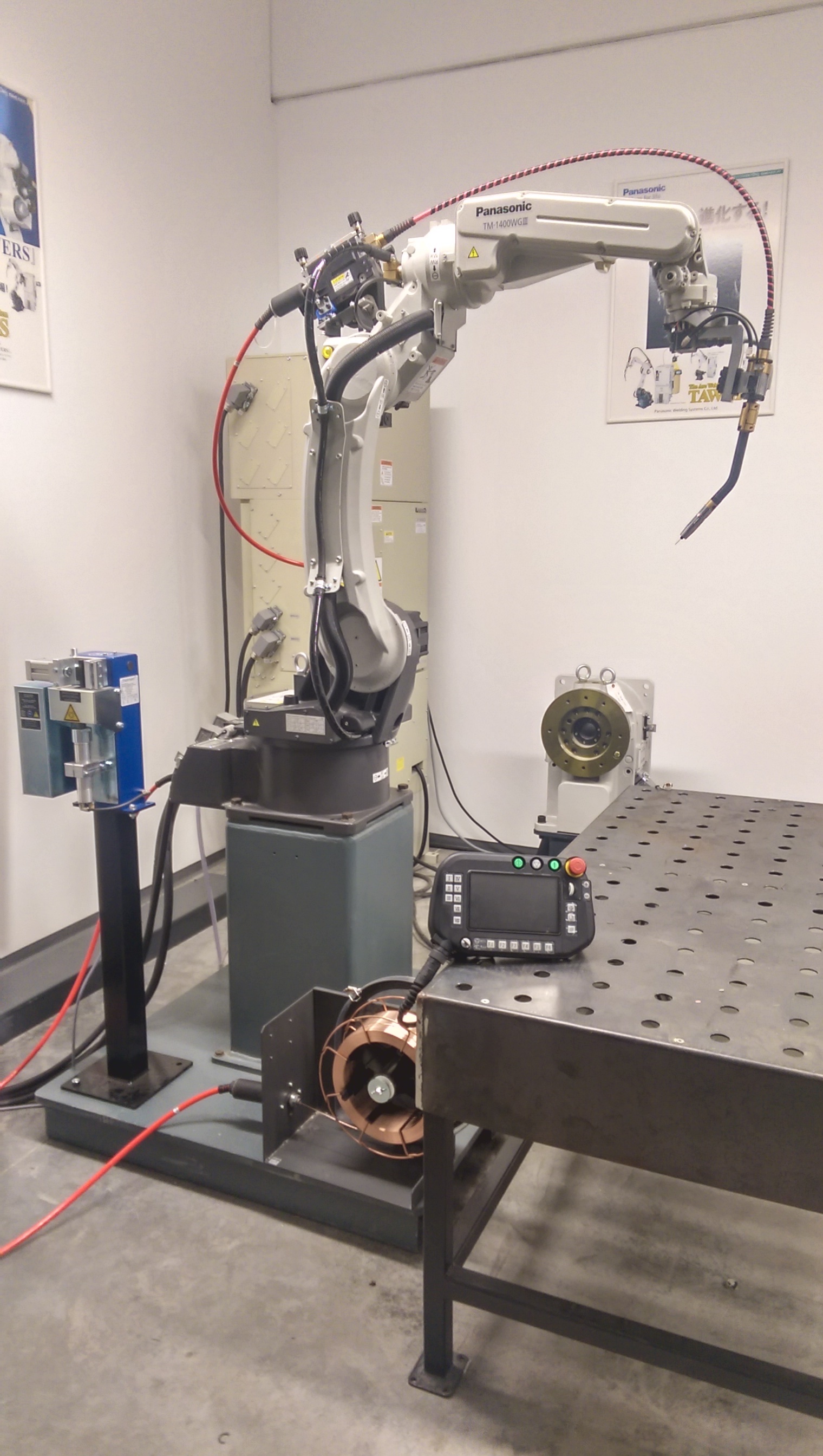

System design: Panasonic PA-H-Frame-S welding robot system

Robot type: Panasonic TM-2000WG3

Power source: Panasonic TAWERS 350A integrated

Welding torch: Panasonic 400A separated water cooled

Positioner: 2 x Panasonic PD1000, 1 x 3m long linear shifter with 2m movability

Working area: 2 x (L=3 000mm x d=1 600mm)

Welding robot system PA-H-Frame-2PD

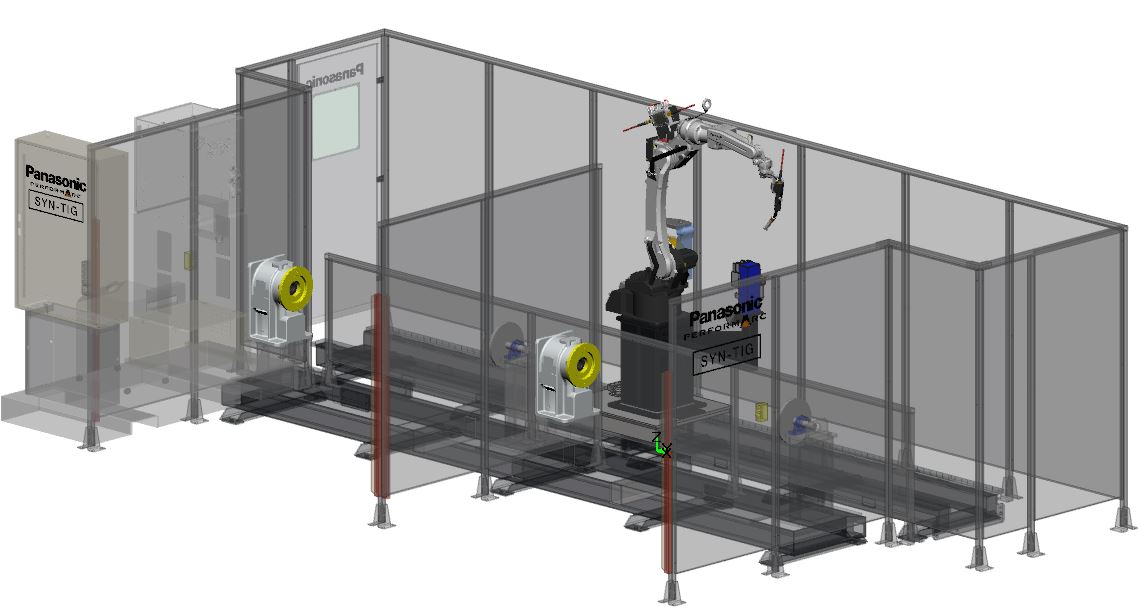

The main features of our own made system:System design: Panasonic PA-H-Frame-2PD welding robot system

Robot type: Panasonic TM-1800Welding power source: Panasonic WG3 (350A) TAWERSWelding torch: Panasonic 400A separate water cooledPositioner: 2 x Panasonic PD500 (500 kg payload)