Super Active Aluminum Welding Process

Panasonic Stitch Pulse software for aluminum welding

(SAWP software option)

This unit is “Pulse STITCH” function an optional software of Panasonic welding robots TAWERS series. It is a stitch welding process that combined active welding and pulse welding. It can produce finely rippled beautiful weld bead appearance The function is effective especially for aluminum welding.

The Panasonic Stitch Pulse welding function

In the case of the Stitch Pulse procedure, the power source is used alternately "on and off". In aluminum welding, Panasonic has taken another step forward in the application of Stitch Pulse by integrating Super Active welding into the process. The Super Active process ensures a smooth start by pulling the welding wire out of the molten pool very frequently. If the welding starts with a Super Active process and switches to a normal pulse during the pulse itself, then there is enough energy available for fusion on the one hand, and for arc initiation without spatter on the other. Panasonic provides a smooth start with the Super Active function and switches to a normal pulse as soon as the arc is established, giving the material time to cool. The result is that the melt flows beautifully, which is not possible conventionally.

Moreover, this development is only due to the unique TAWERS platform provided by Panasonic, in which only one CPU controls the robot, the servo-controlled wire-feeder motor and the integrated 100 kHz inverter power source.

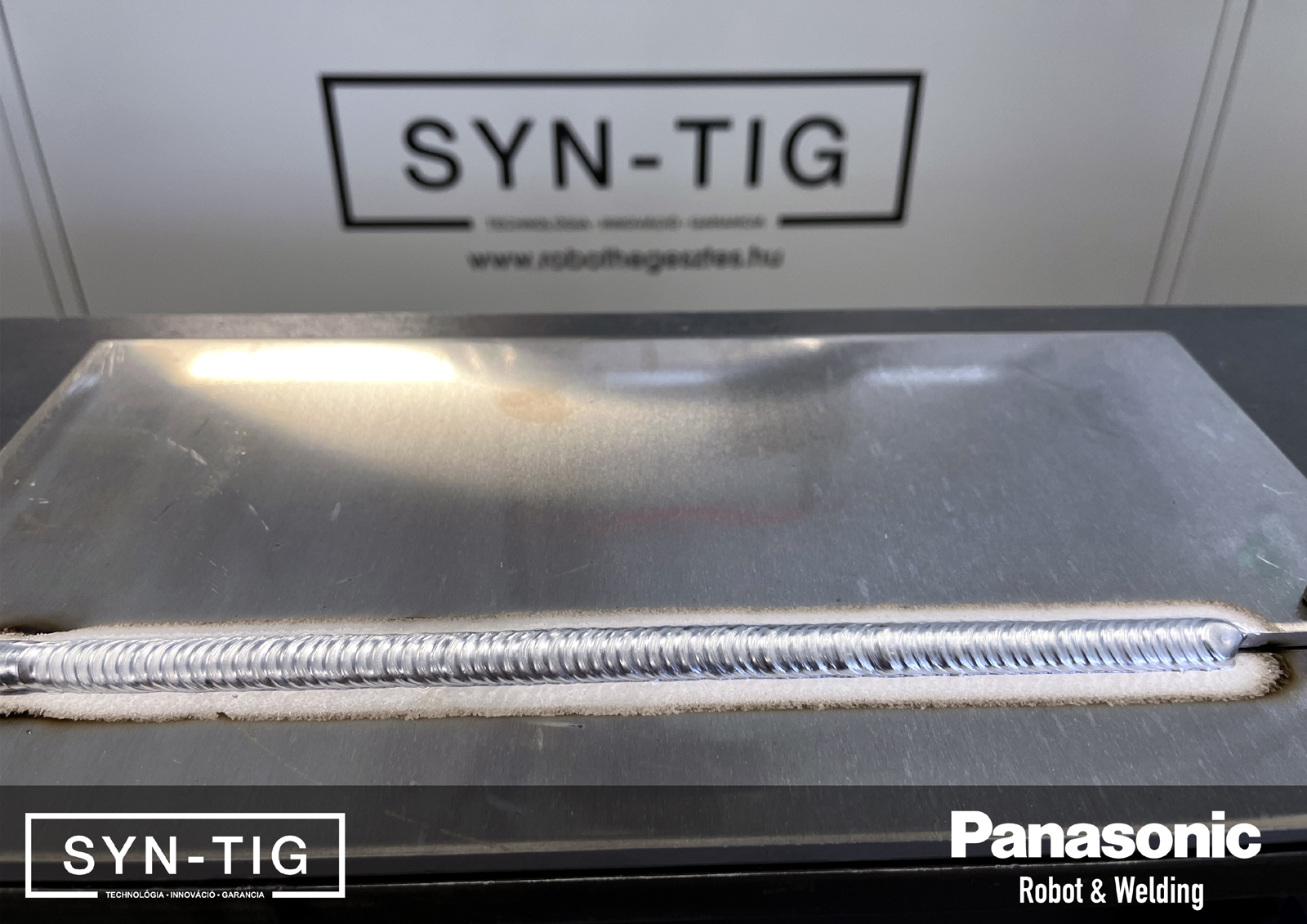

Super Active Aluminum welding process + Stitch Pulse 01

Panasonic active wire feeding + stitch pulse welding software = Perfect aluminum welding!

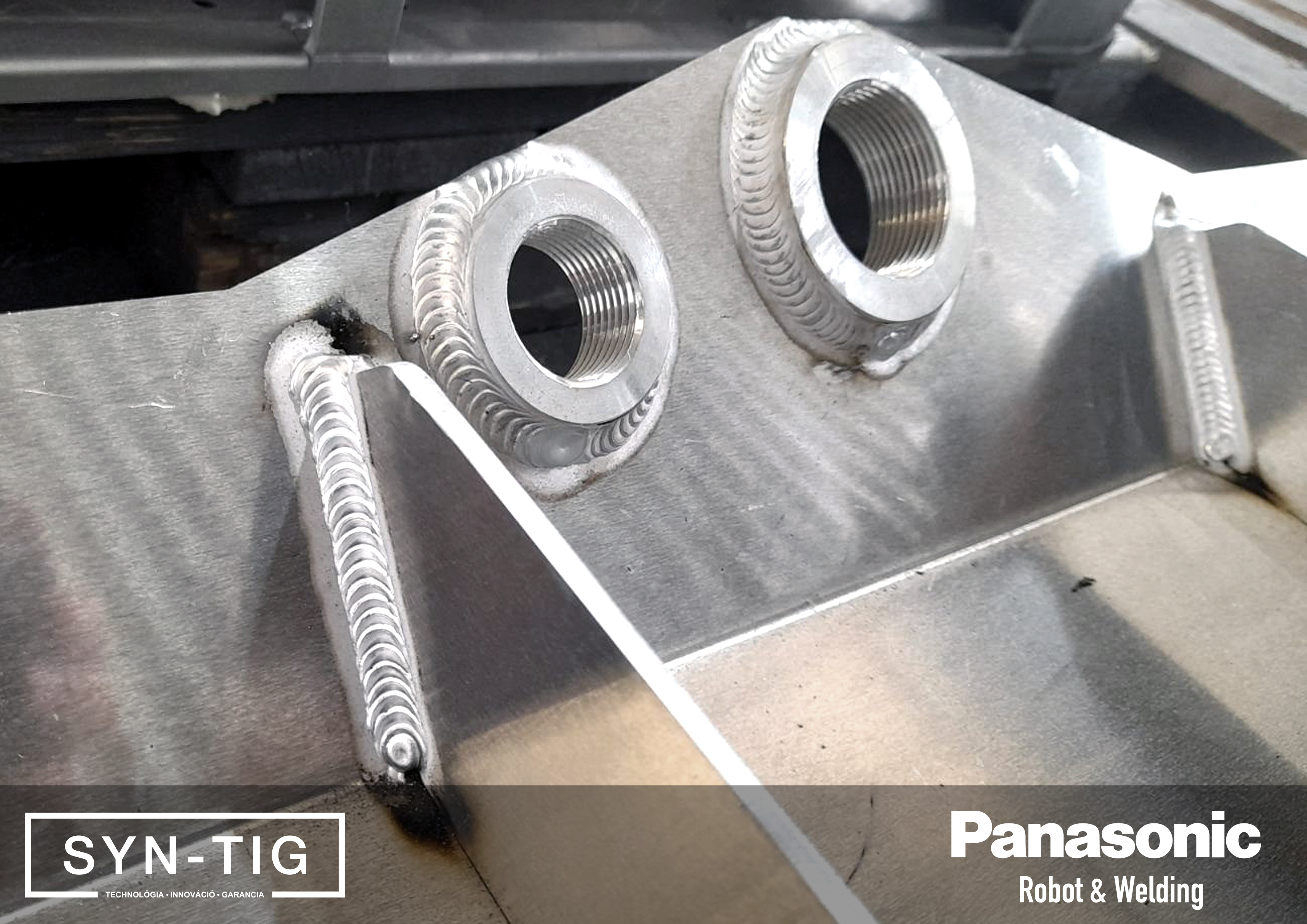

Super Active Aluminum welding process + Stitch Pulse 02

Panasonic active wire feeding + stitch pulse welding software = Perfect aluminum welding!

Super Active Aluminum welding process + P-MIX software

(SAWP software option)

This welding process combines pulse welding and short-circuit welding.

Super Active Aluminum welding process + P-MIX software

Panasonic active wire feeding + Pulse - MIX welding software = Perfect aluminum welding!