Weld navigation software

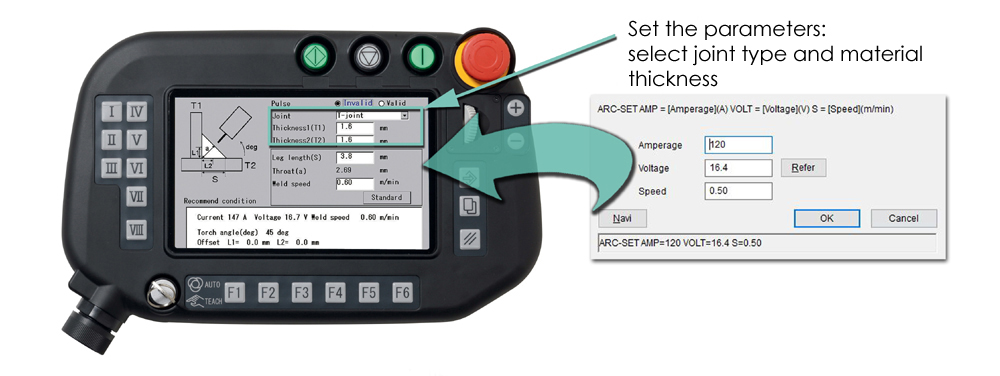

The “Weld Navigation” feature can be compared to a navigation system in the car. It guides the user in the parameter choice utilising a range of “on screen” information data pages ensuring the required welding target is realised. To find the best welding parameter for the application you need only to select joint type and material thickness. The remaining parameter will be automatically calculated by the configured synergy curve and welding speed. Additionally it’s possible to influence the design of throat thickness or joint length to adjust the joint design to specialised requirements. “Weld Navigation”, will automatically re-calculate the new parameter instantly.

New opportunities are now created allowing less experienced programmers with limited welding knowledge to seek and achieve perfect welding results within a short time. It will also allow the welding “expert” to reduce routine remedial work enabling them to concentrate their skill and know-how on product optimization.

„So easy to use as a GPS navigation system in the car”

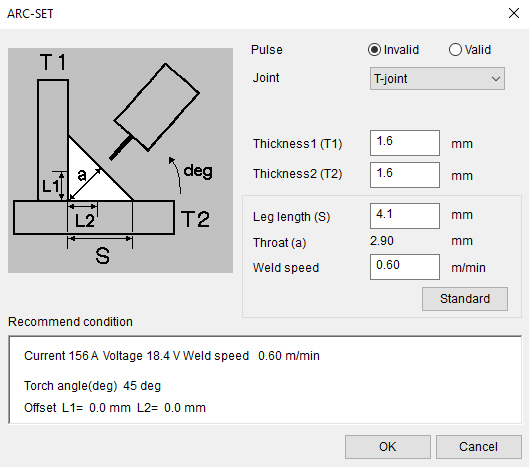

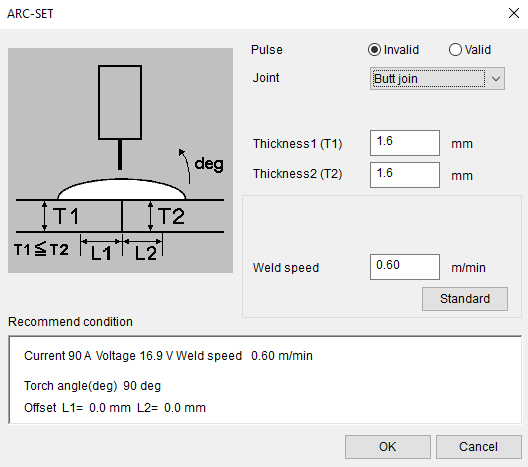

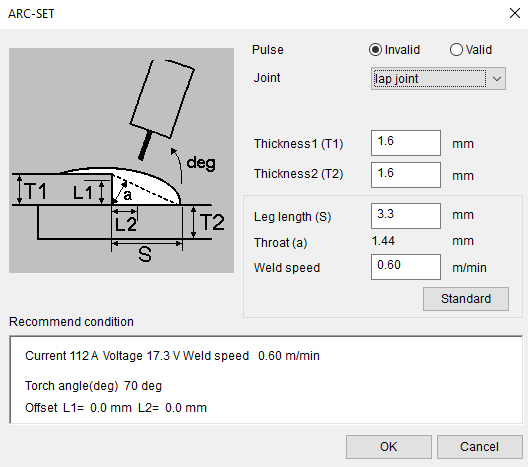

Three different welding shape can be set

T-Joint

Butt joint

Lap joint

Parameter input

The integrated inverter pulse power sources of the TAWERS-WG3 arc welding robots are perfectly suited for MAG, MIG and TIG welding applications. Optimal welding processes can be realized by integrating the inverter power source and the robot control unit, thus ensuring the full cooperation and control of the system.

A new additional feature of TAWERS technology, the welding navigation software, guides the user like a navigation system in the car. After entering the basic data, the navigator determines the required welding parameters. This makes programming much faster and easier.

Information to be provided:

- Seam shape and material thickness

- Easy entry of welding parameters:

1. Specify the thickness T1 + T2 of the workpieces to be welded and the type of joint.

2. Set the requested leg lenght and weld speed.

That's all! The Navigator calculates the recommended welding parameters.

This feature was not known to older Panasonic robots either. This can only be done with the integrated TAWERS WG3 welding robots only.