Panasonic Weld Data Management Function

What is Panasonic Weld Data Management software?

The integration of Panasonic welding data management software into the TAWERS system allows complete control, logging and recording of welding processes. Up to 50 "seam monitors" can be set to check welding data, in which warning and error messages can be defined. The Panasonic welding data management software is a tool that includes "Weld data recording" and "Welding Data Log" logging of welding data.

Welding data management software has 3 main functions:

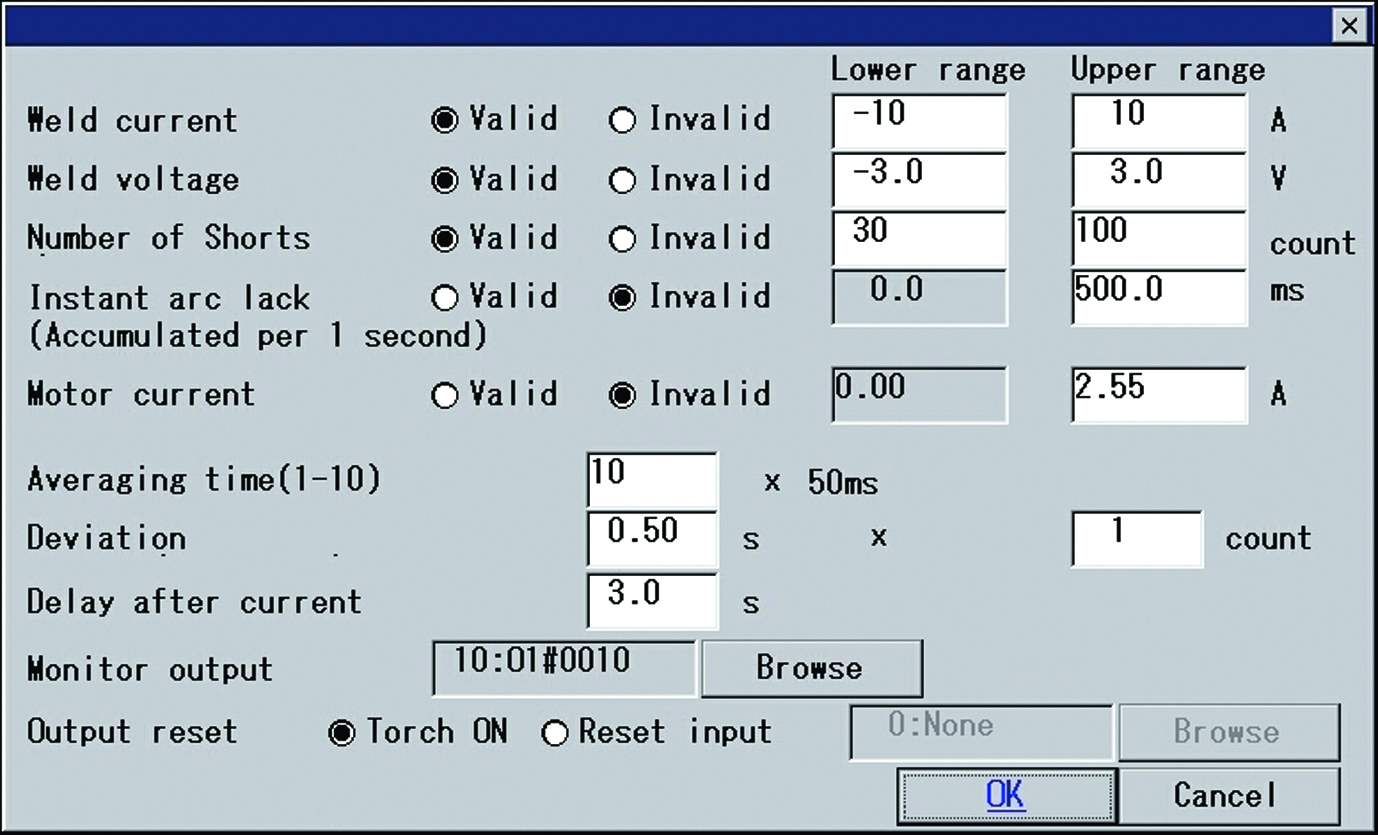

1. Weld Data Monitoring

Monitoring welding condition and output of welding status.

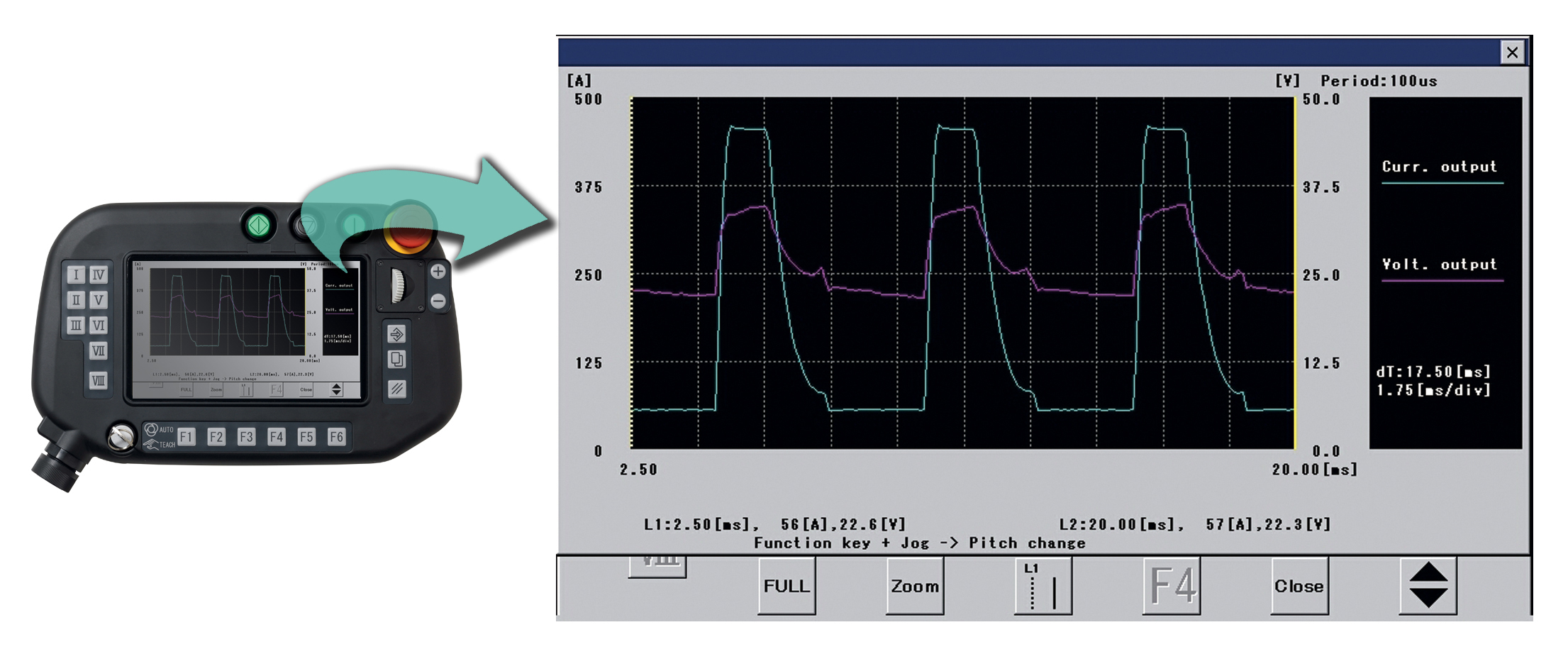

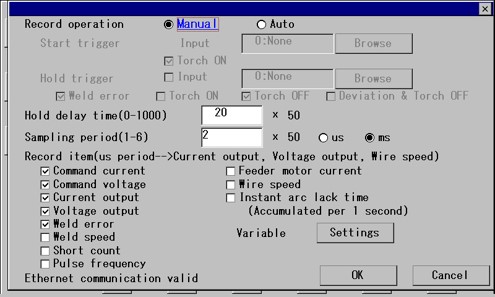

2. Weld Data Recording

This function records status data of welding conditions (such as welding current/voltage and number of short circuit) at welding per a very small unit of time. It is useful to analyze or review welding conditions. Graphical representation of the recorded data on the screen of the teach pendant is also available.

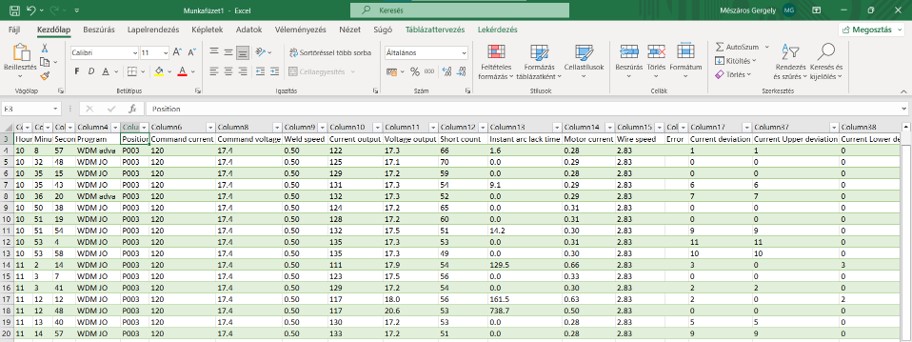

3. Welding Data Log

It is a function that records status data of welding conditions similar to the “weld data record” function, but it collects status data in units of weld point. For example, it can records welding current/voltage of the first weld point, the second weld point and so on of Prog0001. Therefore, the data is useful to check the welding condition status of a certain numbered weld point of a certain numbered workpiece on a certain day.

Ethernet communication

For futher informations please feel free to contac us.