Panasonic TAWERS welding robots

Panasonic TAWERSTM - The only one!

WE DON'T PROVIDE ROBOT MANIPULATOR ONLY, WE PROVIDE COMPLETE WELDING SOLUTION!

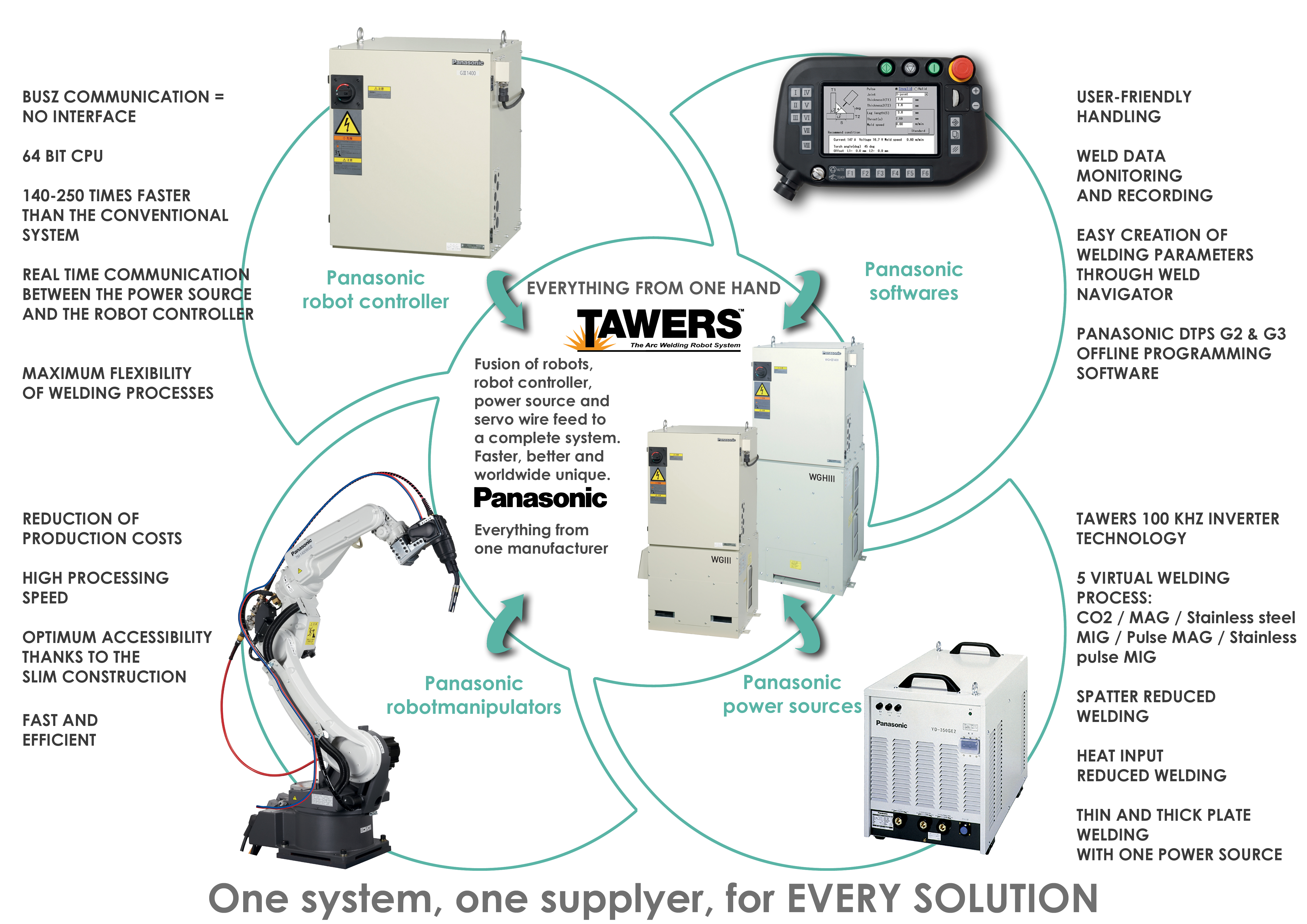

Panasonic TAWERS technology is the latest generation of welding robots. Robot and controller fused with welding power source and servo wire feeder to one unit. Faster, better and worldwide unique. All from one manufacturer that pays off. It is the first and only robotic system in the world where welding power source control (CPU) is 100% integrated into the robot controller. The TAWERS Arc Welding System with integrated inverter pulse power source is suitable for MAG, MIG and TIG welding applications. Optimum welding processes are achieved by utilizing an integrated inverter power source within the robot controller, ensuring complete synergy within the common control system. This ensures that the established benefits and advantages of the existing TAWERS Fusion Technology are also now available for use for the range of MIG, MAG and DC TIG welding process. The TAWERS Fusion system can be easily modified to operate in each of the different welding processes. It requires only the MIG/TIG –base package, welding torch and the WG- MIG/TIG Software.

NO SEPARATE WELDING POWER SOURCE = INTEGRATED ROBOT WELDING SYSTEM

Some of the benefits of Panasonic TAWERS technology

- "All From One Hand" - Main system components are Panasonic developments and products (Robot manipulator, robot controller, welding power source, servo wire feeder, positioners, welding torches, software ... etc.)

- "All-In-One", "One Source Responsibility"

- BUS communication between power source and robot controller

- Real-time synchronization between the welding power source and the robot controller (Integrated system)

- Fully software-controlled welding arc (software upgradeable future)

- Automatic arc length control

- Weld data management function

- Pioneering process control, exceptional productivity

- Servo wire feeder unit integrated into the robot arm

- Real time control of welding parameters

- One unit = 5 virtual power sources: MIG / MAG / PULSE / HD PULSE / TIG DC

-

TAWERS offers all these welding processes:

- SP-MAG

- Hyper DIP Pulse (HD-Puls)

- Active Wire Process (AWP)

- Super Active Wire Process (S-AWP)

- Hot Active and Active Aluminum Process

- MAG-Heat

- MTS-CO2

- MIG Synchro Pulse

- PULL AC-MIG and DC-TIG

- ZI-Tech Process

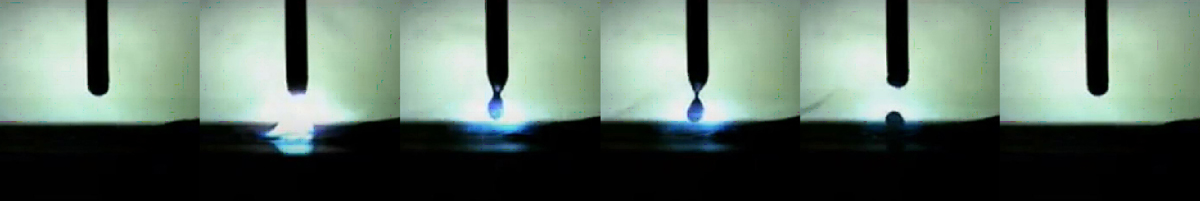

- The technology allows for a well-controlled pulse frequency and targeted drop material transition.

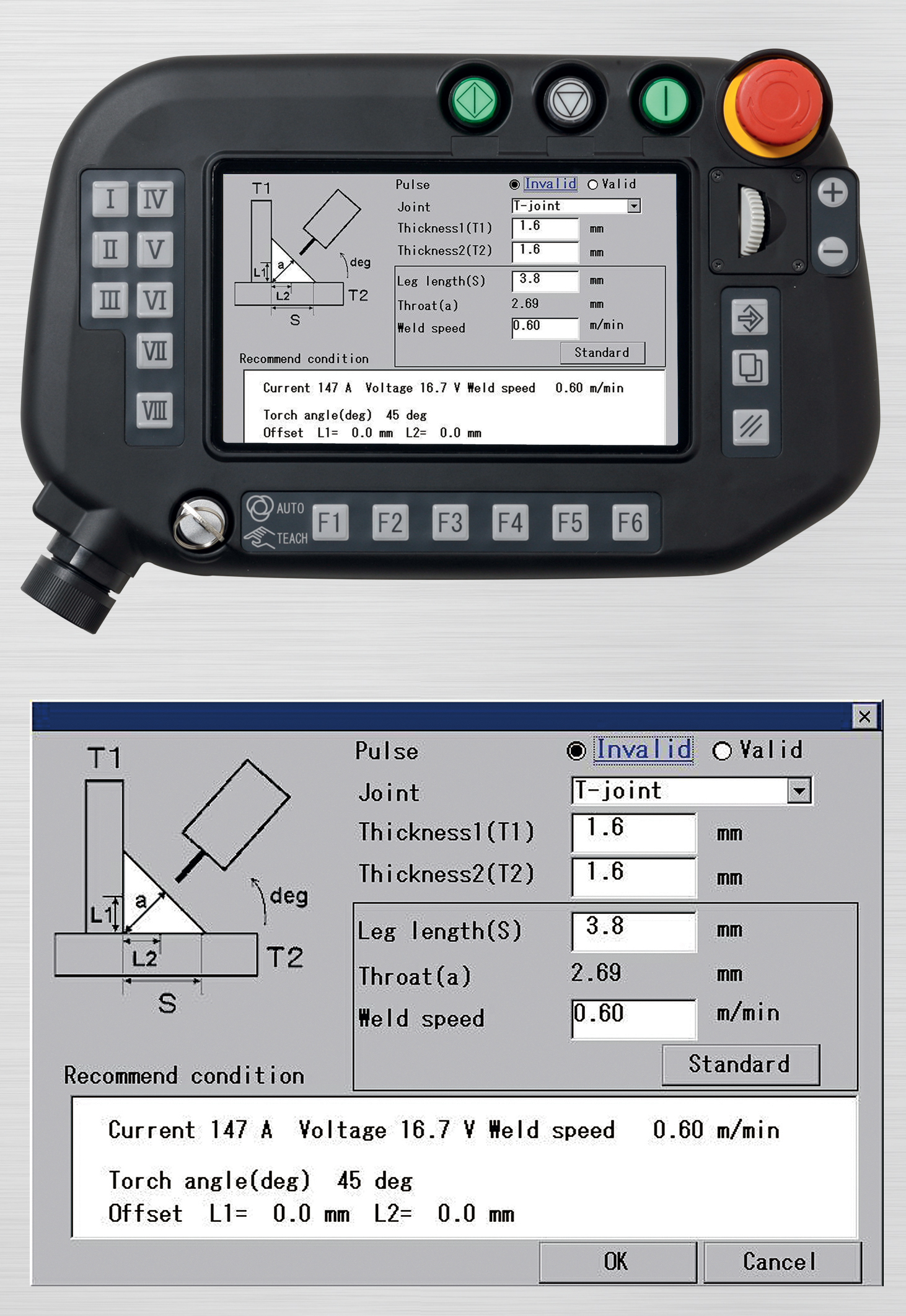

The TAWERS Weld Navigation Software

This function derives the recommended welding conditions from applied joint shape and thickness of the plate. The function is applicable to TAWERS (WG3 controller).

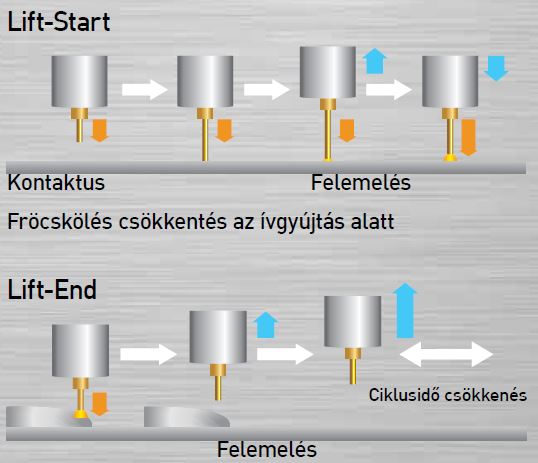

TAWERS LIFT START and LIFT END FUNCTION

“Lift start” provides stable arc start with minimal spatter generation. As this function actually lift up the torch by moving the robot, it allows higher responsiveness compare to retracting the wire.

“Lift end” contributes to reducing cycle time by shortening the wire burning time and also suppressing wire stick generation, thanks to the method to lift up the torch.

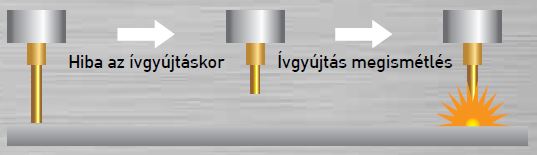

ARC RETRY FUNCTION

It is a function to be used if the welding machine failed to generate an arc at arc start. The robot automatically shifts its position to retry arc start action.

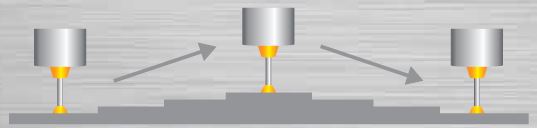

AUTO EXTENSION FUNCTION

(For MIG / MAG / TIG welding processes)

It is a function that absorbs height wise error and distortion of the work (if occurred) by adjusting the torch position to attain stable welding. Therefore, this function is useful for welding of a work that may be distorted by welding heat or welding of eccentric pipes.

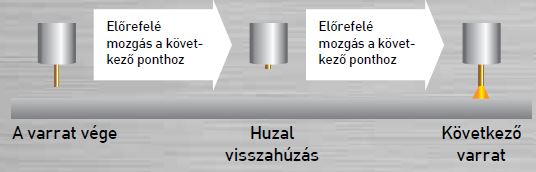

AUTO WIRE RETRACT

Specifies the wire retract time

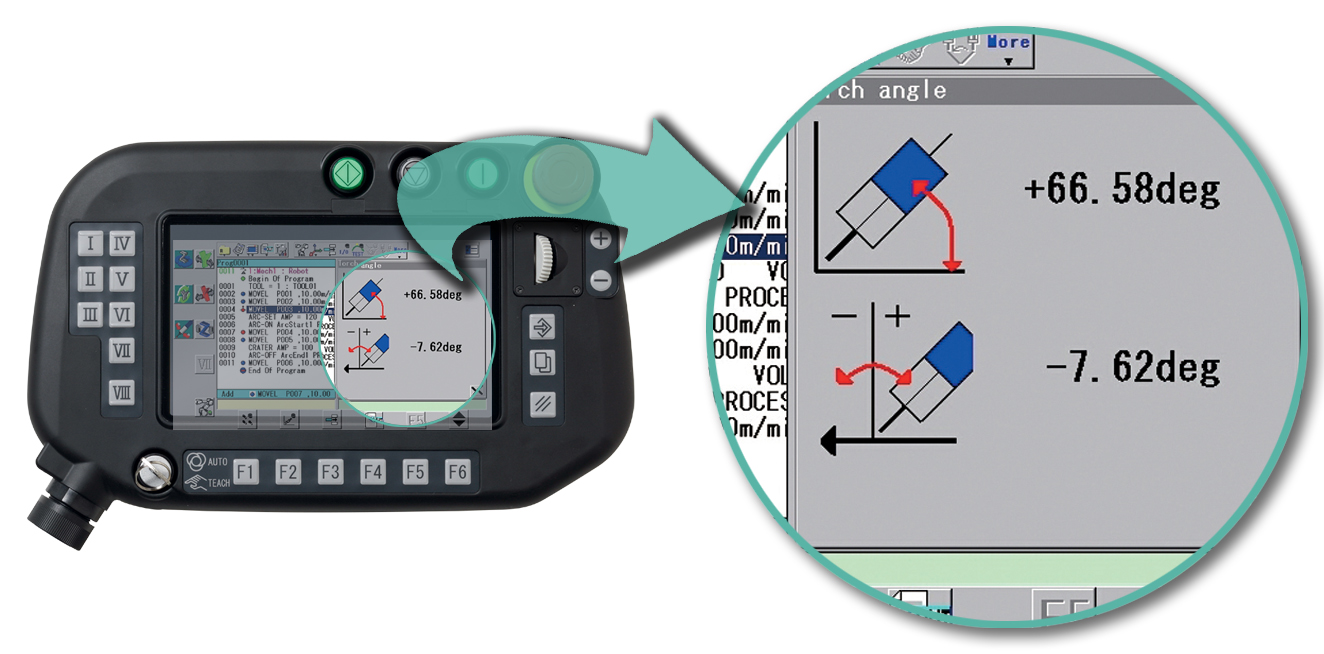

TORCH ANGLE DISPLAY

It is possible to see the actual torch angle values on the teaching pendant

Accident prevention with the ANTI COLLISION function! The robot arm stops when it hits (standard).

- Offline programozással (DTPS) tetszőleges hegesztési folyamat lemodellezhető, majd a robot vezérlőbe áttöltve a hegesztőrobot elvégzi a feladatot. Ez nagyon komplex, bonyolult feladatok megoldására is alkalmas, nem kell előre legyártani a fixtúrákat és a próbadarabokat, csak majd azután, ha megterveztük a teljes folyamatot.

- A WELD DATA monitor mindent rögzít, utólag is minden visszakereshető a gép életéből (opcionális).

- Opciós esetben automatikusan észleli a munkadarab esetleges elmozdulásait és ezáltal a varrat helyét "Touch Sensor".

- Az "Arc Sensor" garantálja az állandó varratalakot (opcionális).

- TAWERS Active Wire Process (AWP) - Aktív huzaladagolás. (opcionális)

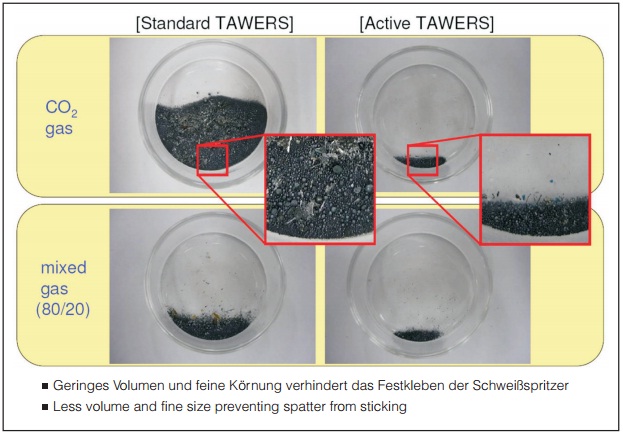

A hegesztési fröcskölés egy jelentős költségtényező a nagyipari termelésben, ezért a Panasonic kifejlesztette az Aktív Huzaladagolási Eljárást (Active Wire Feed Process) a hegesztési minőség tovább javítására és a költségek egyidejű csökkentésére. A jobb előtoló rendszer bevezetésével, a dobra rögzített huzal rásegítővel (Wire Booster), valamint a szoftverrel az új „Aktív TAWERS” rendszer stabil hegesztési minőséget teremt jelentős fröcskölés csökkenéssel, kényszerhelyzetű hegesztés során is. Ezzel elhagyható a robot 4-görgős huzal előtoló mechanizmusa. Továbbá az AWP csökkenti a fröcskölés mennyiségét és nagyságát is. Az eljárás kiváló minőséget és nagyobb beállítási szög tartományt nyújt CO2 hegesztés során.