Panasonic G4/WG4 robot controller - NEW

WG4 and G4 are flagship models of welding robots.

These robots solve customer challenges through a variety of approaches, such as by providing further evolved weldability, ease of use, and safety.

Supporting Factory Optimization - Next-Generation Robot Controller

Supporting Factory Optimization due to Improved motion accuracy,with Touch panel and 3D display and Open interface specifications.

Highly accurate and efficient welding experience

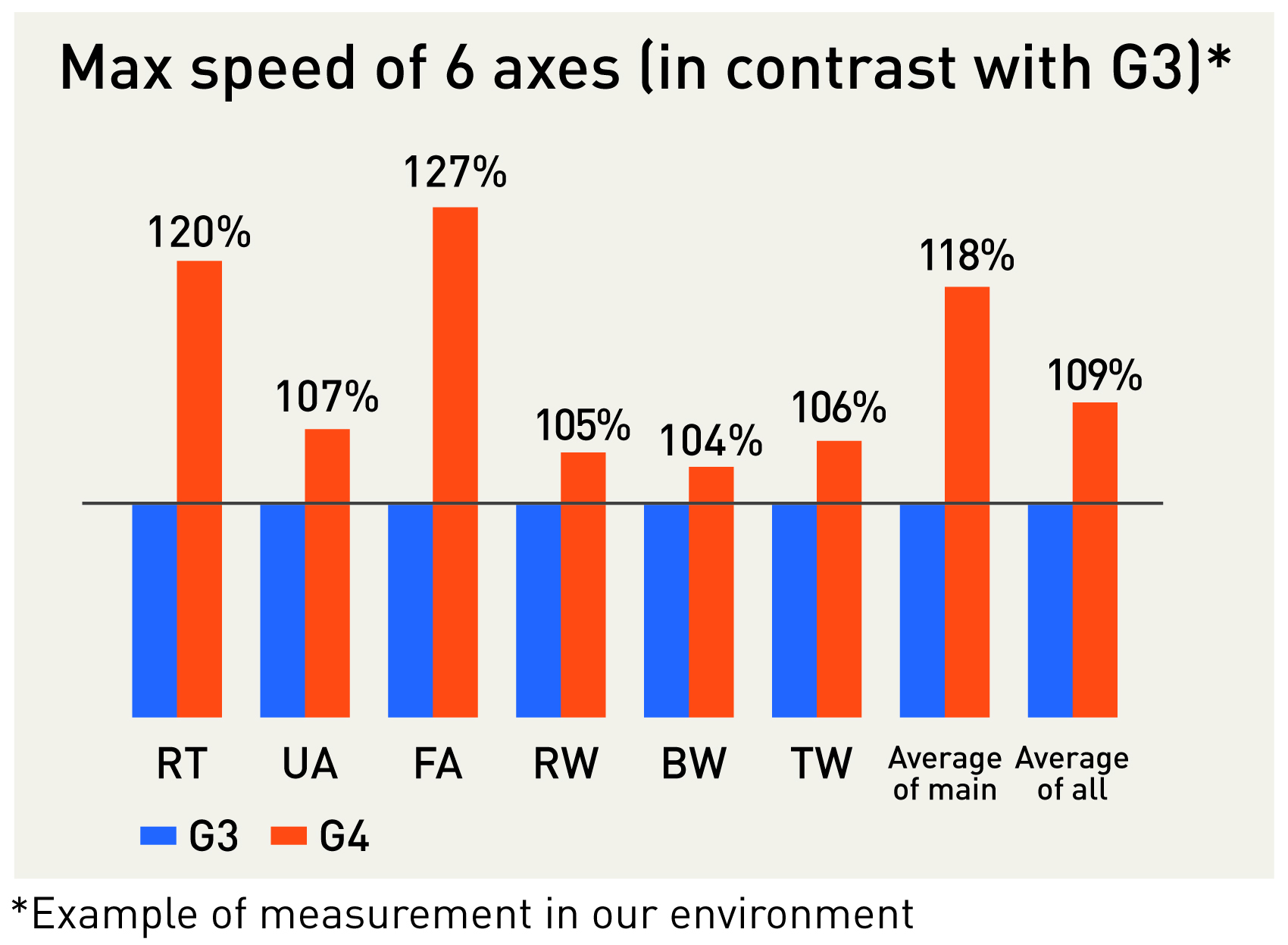

The maximum speed of each axis has improved by up to 27% by fine-tuning acceleration/ deceleration control. The operation algorithm has also been reviewed to improve locus accuracy. These improvements can significantly reduce work lasses that affect productivity in demanding workplaces. Further, this helps to improve product quality, which is indispensable to business success.

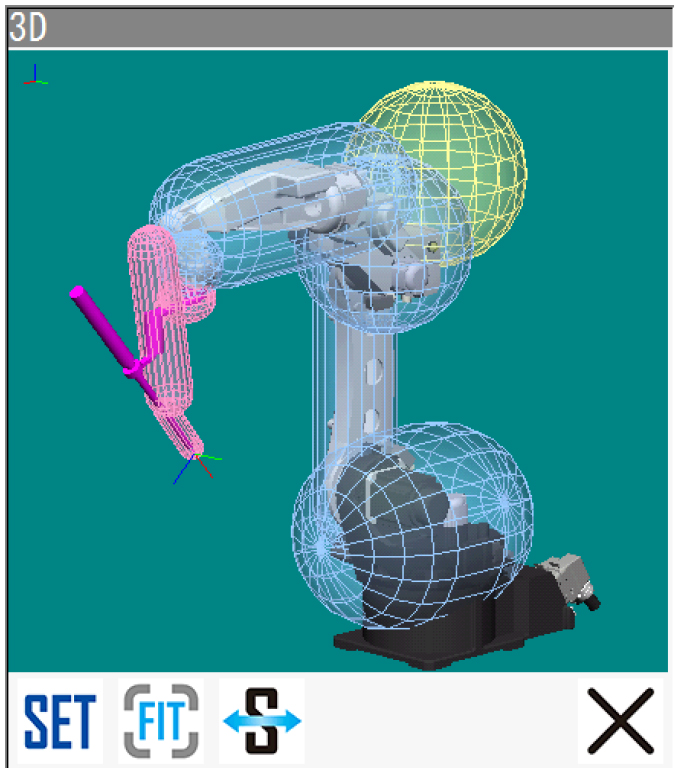

Easier to use with touch panel and 3D display

Equipped with a touch panel with a resolution 1.6 times greater than that of G3, which can be operated with work gloves on, and a 3D engine adopted for the first time, this controller realizes a high-definition 3D display and intuitive operations, herefore making it easier to use.

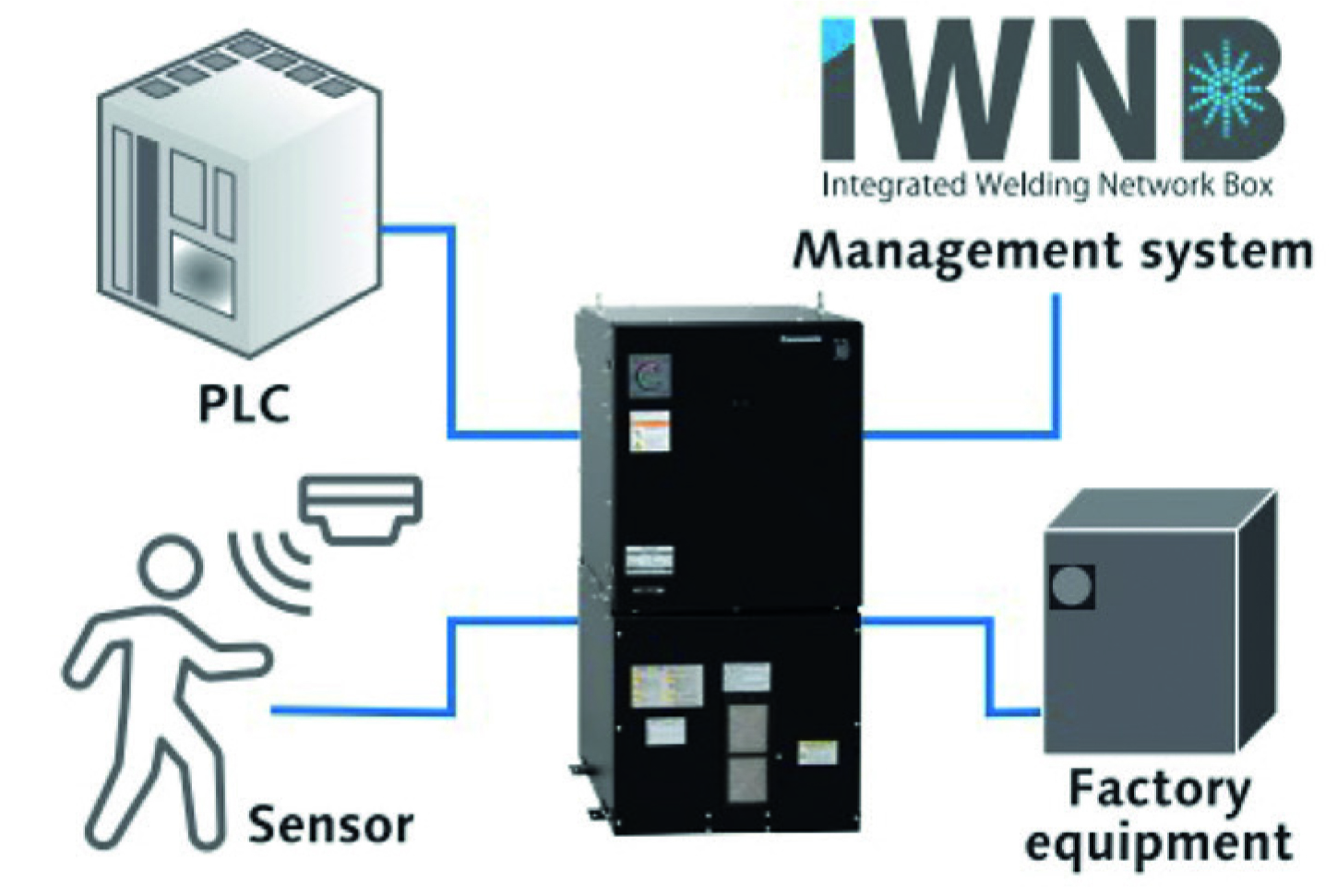

For manufacturing where everything is connected

The G4 controller realizes various functions not available with G3 by utilizing its high speed and parallel processing capabilities. In particular, the adoption of open communication specifications called OPC UA and software-based functional safety with excellent flexibility are typical examples. Connection with new sensors for safety and other devices for data collection or automation will be made easier without any compatibility restrictions with additional devices or hardware limitations.

Cables arranged on the back to save space

The primary side input line and connection cables are arranged on the back and the TP Cable is arranged on the front to reduce projections on the side*.

Features

-

Reduces spatter by approximately 60% with the MTS-CO2 welding method (WG4)

-

Welding control optimization according to robot posture reduces cycle time (WG4 / G4)

-

The teach pendant equipped with a touch panel further improves ease of use (WG4 / G4)

-

Eliminating the need for an external step-down transformer reduces the man-hours required for setting up at sites outside Japan (WG4 / G4)

-

The conformance to the OPC UA standard facilitates integration with peripheral devices (WG4 / G4)

-

The software-based safety mechanism enables more flexible and safer work environments (WG4 / G4)

Speed comparison video WG3 - WG4.