TM-1100/1400/1600/1800/2000

New Generation Panasonic TM Welding Robots – Precision Industrial Solutions

The Panasonic TM series welding robots represent the latest technology in industrial robotic welding. Featuring a highly rigid arm structure, powerful servo motors, and advanced motion coordination, they ensure precise positioning of the welding torch. Flexible cable management—whether internal, external, or separated—allows the robot to easily adapt to various industrial environments. An ideal choice where reliability, accuracy, and efficiency are essential.

One arm - three different cable management

Cable Management Options for Panasonic TM Welding Robots

The Panasonic TM series welding robots offer three different cable management solutions, allowing easy adaptation to the specific welding task, workspace, and robot arm motion dynamics.

Separated Cable Management

In the separated configuration, the power cable—similar to the internal cable version—runs through a central hollow axis to reach the welding torch connection point. However, the wire guide tube is located externally. This setup results in lower inertia because the external cable system has less mass, which positively affects the control of the robot’s rapid movements.

Internal Cable Management

The internal configuration uses a cable bundle routed through a hollow axis parallel to the robot arm. This significantly reduces the cables’ moment of inertia and minimizes interference during robot motion. All cables, including hoses, are fully protected, making this solution ideal for complex welding environments, such as tight workspaces around fixtures or clamps. Additionally, continuous visual monitoring is unnecessary during robot programming because the cables move safely and discreetly.

External Cable Management

In the externally mounted version, the cable bundle runs along the outside of the robot arm, following a gentler curve. This design reduces internal friction and is an excellent choice when cable twisting could be a concern. It provides a simple and efficient solution for tasks where easy access to reliable cable management is important.

Innovative Solutions in the Panasonic TM Welding Robot Series

The Panasonic TM series welding robots offer numerous innovations for precise and cost-effective robotic welding. The completely redesigned safety torch holder, with an integrated emergency stop, ensures a consistent Tool Center Point (TCP), even during extreme cable movements. The cable bundle routed through the robot body follows an optimized path, reducing bending stress during rapid robot motion.

Stable cable management not only increases system reliability but also significantly improves wire feed accuracy—directly contributing to higher welding quality.

Production quality control is also simplified with the built-in “Quick Check” system. This predefined test position, located on the robot base, allows the torch to be quickly visually inspected via the control panel. Operators can immediately detect deviations and correct them efficiently.

In developing the TM series, Panasonic responded to modern industrial requirements: higher productivity, cost reduction, and even more precise automated welding. The result is a robotic welding solution that provides a long-term competitive advantage.

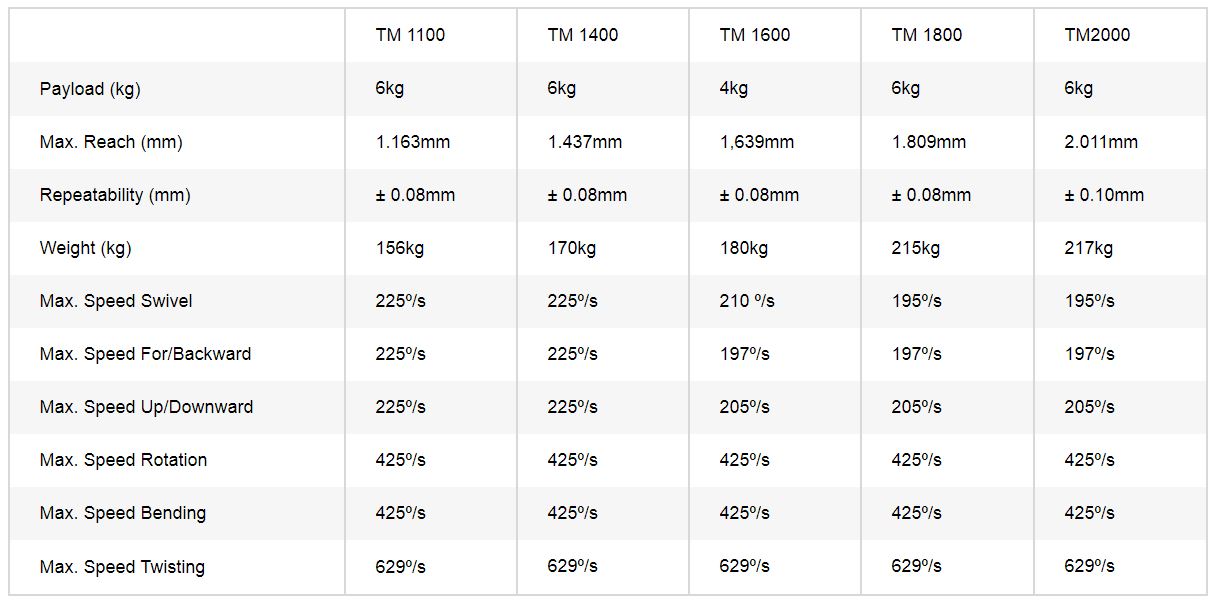

Specifications