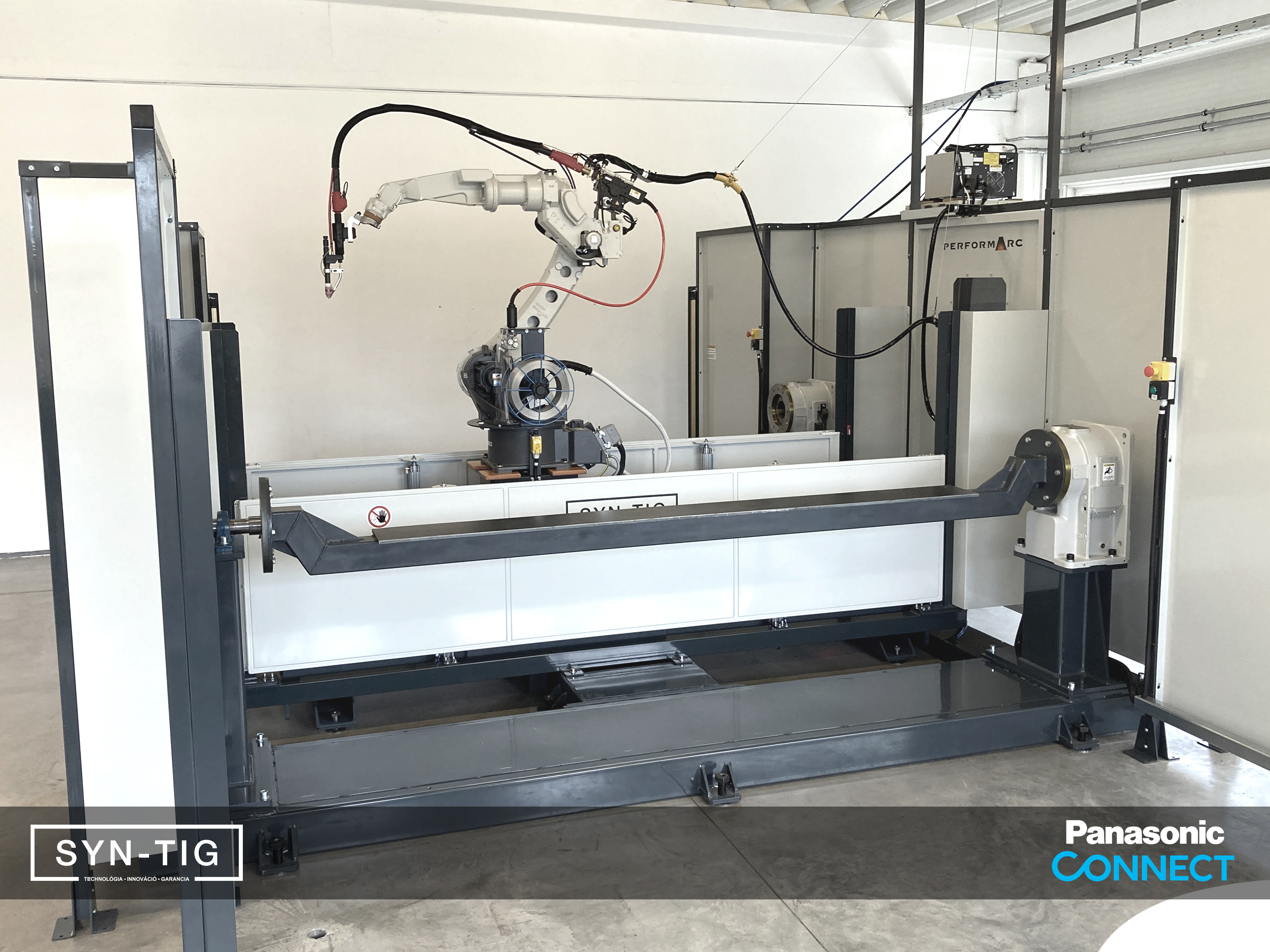

Panasonic PA-H-Frame-TIG system

Own developed welding robot system for TIG Welding

System designed by our company

Production of all structural elements in Hungary

Self-developed and manufactured electrical control cabinet

Complete Panasonic robot and welding technology

CE conformity

Standard features

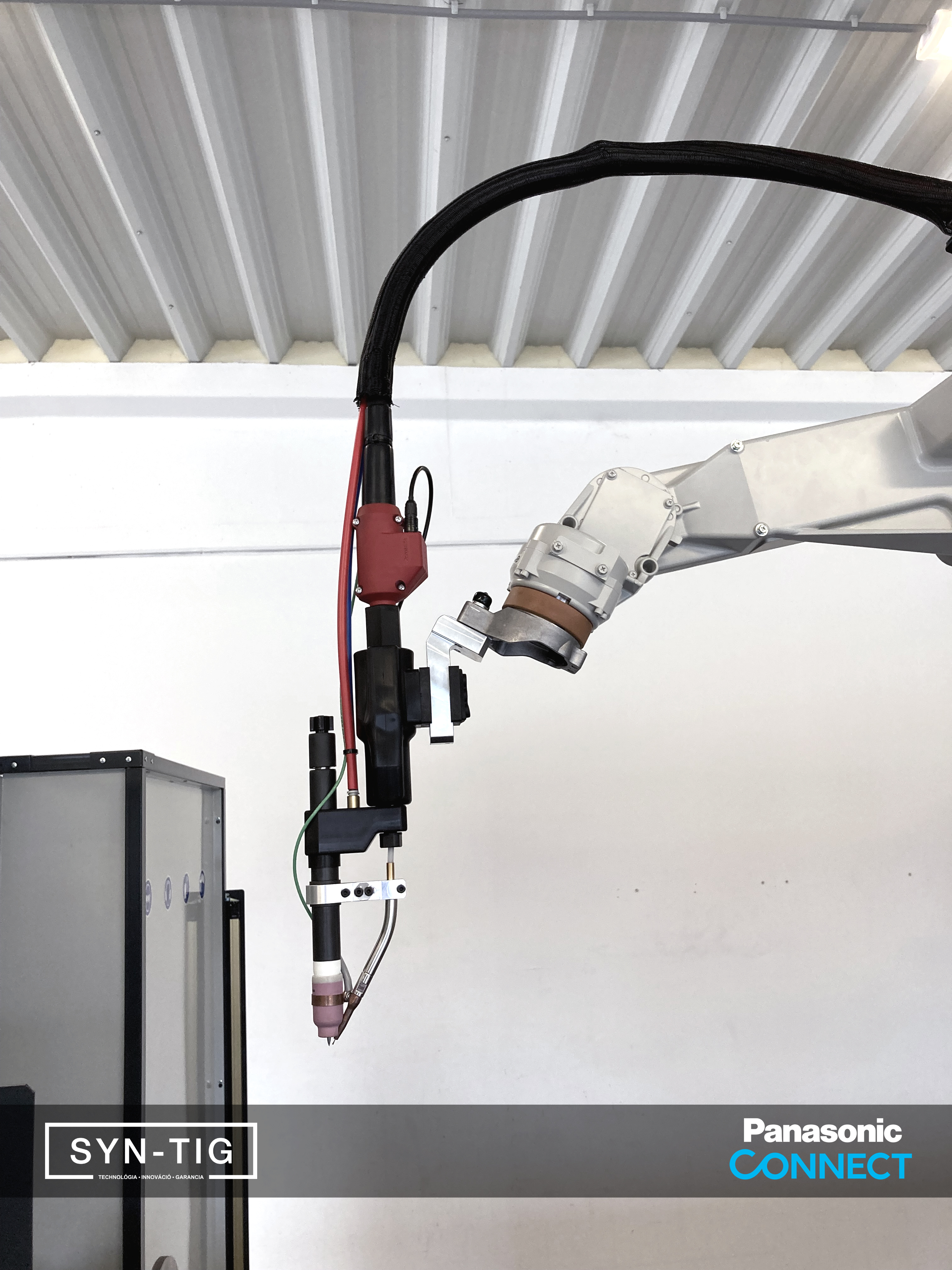

Panasonic TM -1800WG3 (TAWERS) robot manipulator

Panasonic 350A integrated TIG power source (Modification to MIG/MAG is possible)

Panasonic G3 robot controller with teaching pendant and 10m cable

Panasonic 4-roller servo wire feeder integrated in the robot arm

Panasonic 300A external type water-cooled welding torch with safety holder

Panasonic PD500 positioning device (2x) (Load capacity: 500 kg per side, which can be expanded as an option)

Panasonic Ethernet card

Panasonic I / O expansion card: 32 inputs / 32 outputs

Self-developed complete welding robot system

Working area 2 x (L = 3,000mm x d = 1,300mm)

Protective walls and safety equipment

Control panels

Water cooling unit

Electrical control cabinet

Approximate system dimensions: L x W x H approx. 6.0 x 5.4 x 2.4 m

Approximate weight: 3,000 kg

Options (Including but not limited to)

1000kg payload positioner

Bigger working area

Linear shifter

MAG / MIG package

Properties

All important elements of the Panasonic PA-H-Frame-TIG welding robot system are Panasonic development and production (Robot manipulator, integrated welding power supply, robot controller, positioners, wire feeder, welding torch, welding software, etc.)

"All from one" - system solution to reduce the number of suppliers of different interfaces = increase productivity.

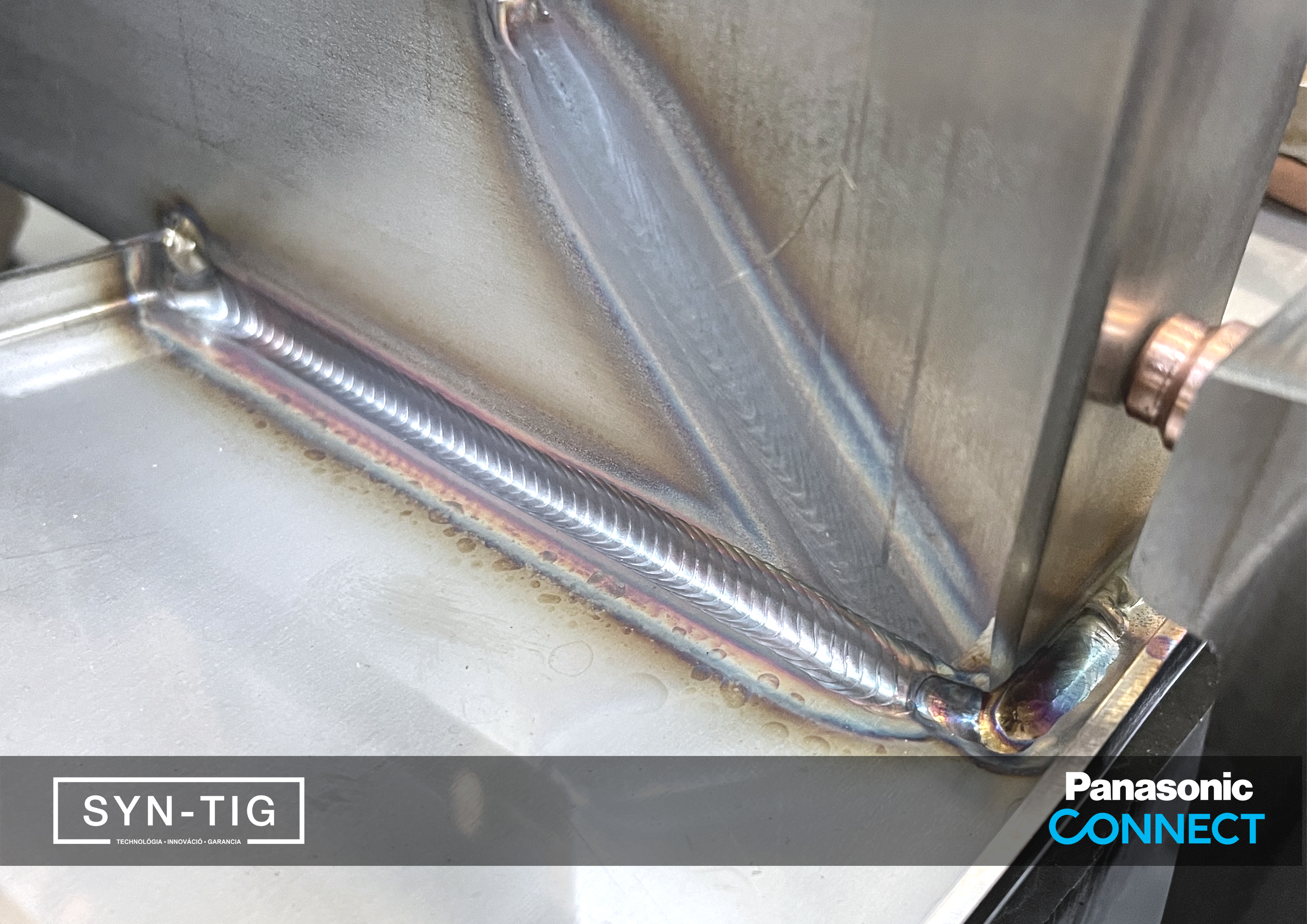

High quality arc welding, high production rate.

Distortion-free design, programming for easy transport without correction.

Easy program sharing when using multiple robots to increase productivity.

Customer benefits

Panasonic "all from one" welding technology - no separate interface between the robot and the power supply!

Being an integrated welding power source, there is no need to learn the controls of the welding power source

Optimal setting of all welding parameters using the Windows-based teaching pendant

Economical and flexible system solutions

Tested before shipment

Continuous Hungarian system production

Possibility to test at our site, incl. welding tests on customer part.