Weld navigation software

Panasonic Weld Navigation is an innovative, intelligent welding support system developed by Panasonic to simplify and optimize robotic welding processes. This system is especially useful for those who need an efficient and user-friendly solution for setting and fine-tuning arc welding parameters.

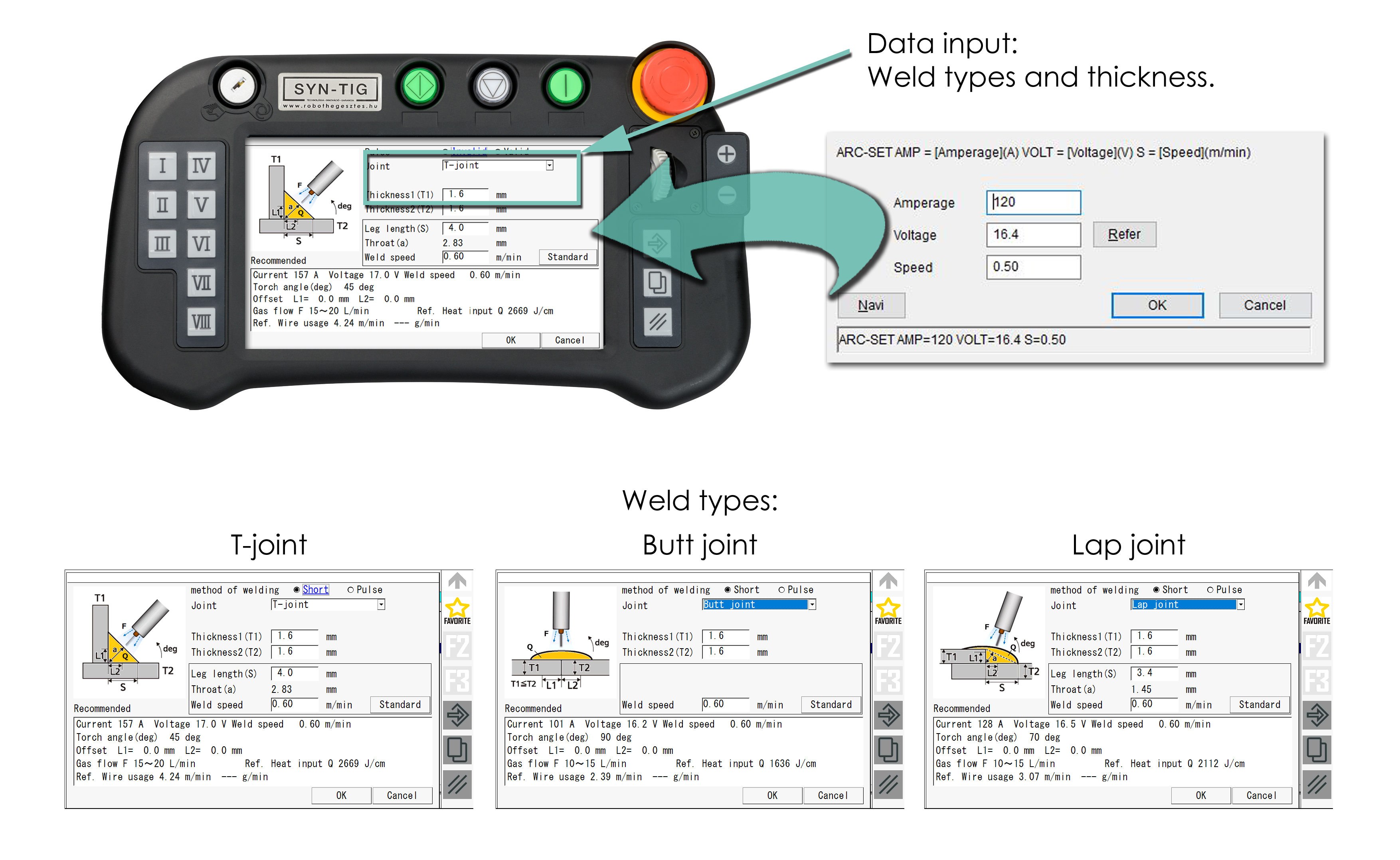

With “Weld Navigation,” Panasonic introduces the latest feature of its existing TAWERS robot systems, enabling simpler and faster welding. This function can be compared to a car’s navigation system. By using a series of on-screen information displays, it assists the operator in selecting the right parameters, ensuring that the desired welding goal is achieved.

To find the most suitable welding parameters for a given application, the operator simply selects the welding position (e.g., fillet, lap, or butt joint), material thickness, and welding speed. The system then suggests the most optimal settings. This creates new opportunities for less experienced programmers with limited welding knowledge, allowing them to achieve perfect welding results in a short time.

For welding experts, this means reduced routine maintenance work, enabling them to focus their skills and expertise on product optimization.

“Its use is as quick and easy as a GPS navigation system!”

The latest TAWERS robots (G3 / G4 controllers) now make the innovative Weld Navigation System available, supporting the user in a way similar to a car’s navigation system.

Operating principle:

The user provides the following data:

-

Type of weld

-

Material thickness (T1 + T2)

-

Welding speed

The software then automatically recommends the required welding parameters.

Advantages:

-

Significantly reduces programming time

-

Easier learning process for new users

-

Consistent welding quality

⚠️ Note: This feature is not available for older Panasonic robot models; it is supported exclusively by the TAWERS G3 / G4 integrated systems.